Process Water: Essential For Industries And Businesses

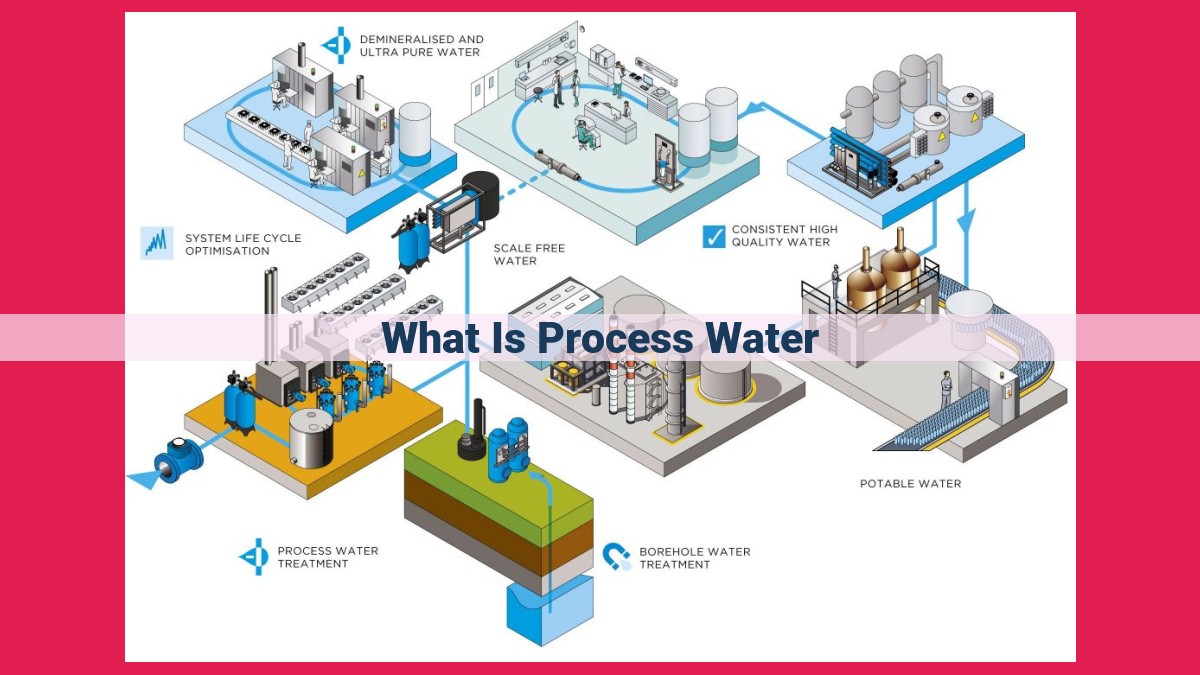

Process water, distinct from potable water, serves diverse industrial and commercial applications. Derived from raw water sources, it undergoes filtration and treatment to meet specific quality standards. Types include industrial, cooling, cleaning, and manufacturing water, each tailored to different applications. Ensuring appropriate water quality is crucial for optimal performance, while understanding related concepts like raw water and demineralized water is essential. Challenges like water scarcity and environmental regulations highlight the need for sustainable water management practices. Process water plays a vital role in supporting industries and businesses, making its efficient and responsible use paramount.

Definition of Process Water:

- Explain that process water differs from potable water, serving various industrial and commercial purposes.

Process Water: The Unsung Hero of Industrial and Commercial Operations

In the realm of water, we often think of it as a resource for our homes, ready to quench our thirst or cleanse our bodies. But beyond the realm of potable water, there exists a lesser-known yet equally vital companion: process water. This workhorse liquid plays an indispensable role in countless industries and commercial ventures, making our modern world possible.

Unlike its potable counterpart, process water is not meant for human consumption. Instead, it serves a diverse array of specific functions, from cooling machinery to cleaning products and everything in between. Its journey begins with raw water sourced from rivers, lakes, or wells. Through meticulous filtration and treatment processes, this raw water is transformed into customized solutions tailored to the demanding requirements of various industrial and commercial applications.

Filtration and Treatment: Tailoring Water to Specific Needs

The quality of process water is paramount to ensure efficient and safe operations. To meet these stringent standards, filtration removes impurities, while softening reduces mineral content. Advanced technologies like reverse osmosis purify water further, removing even trace contaminants. By controlling the quality of the water, industries can maximize their output, minimize maintenance costs, and safeguard the well-being of their workforce and the environment.

Applications: Where Process Water Shines

The versatility of process water is astounding, spanning a wide range of industrial and commercial sectors. From manufacturing plants and power stations to hospitals and hotels, this liquid asset is indispensable. Manufacturers rely on process water for cooling, cleaning, and incorporating into their products. Commercial establishments utilize it for cleaning, landscaping, and cooling systems, ensuring a comfortable and hygienic environment for customers and employees alike.

Water Quality Standards: Ensuring Performance and Safety

To guarantee the desired performance and safety in each application, process water must adhere to specific quality standards. These standards vary depending on the industry and intended use. Parameters such as pH level, mineral content, and the presence of contaminants are closely monitored and regulated. Meeting these standards ensures that process water not only performs optimally but also safeguards equipment, protects human health, and complies with environmental regulations.

Related Concepts: Navigating the Water Landscape

Process water exists within a broader landscape of water classifications. Raw water refers to untreated water in its natural state, while non-potable water is not safe for consumption. Demineralized water, deionized water, and distilled water have undergone rigorous purification processes, removing minerals, ions, or impurities, respectively. Understanding these different types of water helps in selecting the most appropriate solution for specific needs.

Challenges and Considerations: Water Management in a Changing World

While process water is essential, its availability and quality face challenges. Water scarcity, contamination, and increasingly stringent environmental regulations demand responsible water management and sustainable practices. Industries are adopting innovative approaches to reduce water consumption, recycle and reuse water, and mitigate environmental impacts. By embracing sustainability, organizations can ensure a secure future supply of this vital resource.

Process water is the unseen backbone of countless industries and commercial operations. Its versatility, adaptability, and adherence to strict quality standards make it an indispensable resource. As we navigate the challenges of the future, responsible water management practices will be crucial to ensure the continued availability and quality of this precious liquid. By understanding and appreciating the role of process water, we can harness its power to drive innovation, improve efficiency, and safeguard the health of our planet and its inhabitants.

Sources and Types of Process Water:

- Describe raw water sources and how process water is derived.

- List different types of process water, including industrial, commercial, cooling, cleaning, and manufacturing water.

Sources and Types of Process Water

When it comes to industrial and commercial operations, water is an essential resource that serves a myriad of purposes, ranging well beyond human consumption. This water, aptly named process water, differs from potable water in that it is specifically tailored to meet the unique requirements of various industrial applications.

Process water can be sourced from a variety of raw water sources, including:

- Surface water: Bodies of water such as rivers, lakes, and reservoirs often serve as the primary source of process water.

- Groundwater: Water extracted from aquifers beneath the Earth’s surface can also be a viable source.

- Municipal water: In certain cases, process water may be obtained from municipal water supplies, which undergo additional treatment to meet specific industrial standards.

Once sourced, process water is then subjected to rigorous filtration and treatment processes to enhance its quality for specific applications. However, before diving into these processes, let’s explore the diverse types of process water commonly used in industrial and commercial settings:

- Industrial process water: This type of water is used in manufacturing processes, including the production of chemicals, textiles, and food products.

- Commercial process water: Used in various commercial applications, such as cleaning, sanitization, and cooling.

- Cooling water: As the name suggests, this water is employed to cool machinery and equipment, preventing costly breakdowns and ensuring optimal performance.

- Cleaning water: Thorough cleaning is essential in many industrial and commercial settings, and process water plays a crucial role in this process.

- Manufacturing water: This type of process water is specifically formulated to meet the exact specifications required for manufacturing processes, ensuring precise and consistent results.

Filtration and Treatment: Enhancing Water Quality for Process Applications

In the realm of industrial and commercial processes, process water plays a crucial role. Unlike potable water meant for human consumption, process water serves a wide range of purposes, including cooling, cleaning, manufacturing, and landscaping. To ensure its suitability for these applications, filtration and treatment processes are essential.

The Imperative of Filtration and Treatment

Raw water, sourced from various sources like rivers, lakes, or wells, often contains impurities that can hinder its effectiveness for specific industrial processes. These impurities may include suspended solids, dissolved minerals, organic matter, and even harmful microorganisms.

Filtration and Treatment Methods

To address these challenges, various treatment processes are employed to enhance water quality. Filtration removes suspended solids such as dirt, sediment, and particles. Softening eliminates hardness caused by dissolved minerals, preventing scale formation in pipes and equipment. Reverse osmosis is a highly effective technique that removes even dissolved impurities, producing ultra-pure water for critical applications.

These treatments not only improve the performance of process water but also extend the lifespan of machinery, enhance product quality, and minimize environmental impact. By customizing treatment processes to meet specific application requirements, industries can optimize water utilization and ensure efficient operations.

Applications of Process Water: A Vital Resource for Industries and Businesses

In various industries and commercial settings, process water plays a crucial role in supporting operations and ensuring efficient performance. Unlike potable water intended for human consumption, process water has distinct characteristics and serves a wide range of purposes apart from drinking.

One of the primary applications of process water is in manufacturing. In countless factories, it is used as a component in the production of products, serving as a solvent, diluent, or cooling agent. For example, in the automotive industry, process water is utilized in paint booths and metalworking operations.

Another vital function is cooling. In power plants, petrochemical facilities, and other industries, process water is circulated through heat exchangers to dissipate heat from machinery and prevent overheating. This helps maintain optimal operating temperatures and ensures the smooth functioning of critical equipment.

Cleaning is another important application of process water. It is used in a variety of settings, including hospitals, food processing plants, and manufacturing facilities. Process water is employed for cleaning equipment, surfaces, and products to ensure hygiene and prevent contamination.

Beyond these essential uses, process water also finds its way into landscaping and agriculture. In irrigation systems, it is used to supply water to plants, helping them grow and flourish in both indoor and outdoor environments.

It is crucial to note that the type of process water used is carefully selected based on the specific application. Different industries and processes may require varying levels of water quality, purity, and specific characteristics. For example, cooling water may require a lower level of purity than water used in pharmaceutical manufacturing.

Utilizing the right type of process water ensures optimal performance, prevents damage to equipment, and maintains product quality. By ensuring the availability of suitable process water, businesses and industries can optimize their operations and achieve desired outcomes.

Water Quality Standards for Process Water: Ensuring Optimal Performance

Comprehending the significance of process water quality is crucial for maximizing industrial and commercial operations. Establishing specific water quality standards is essential to ensure the proper functioning of equipment and the preservation of product quality.

Various industries have unique requirements for process water, and meeting these standards is paramount. Parameters such as pH level, hardness, turbidity, and dissolved solids are closely monitored and regulated to prevent corrosion, scale formation, and other detrimental effects.

For instance, in the manufacturing industry, high-purity water is often necessary to prevent contamination and maintain precision in processes like microelectronics fabrication. On the contrary, cooling systems may require less stringent water quality standards, focusing on temperature control and corrosion prevention.

Understanding the specific water quality parameters for each application is vital. Regular testing helps ensure compliance with established standards and allows for prompt corrective actions when deviations occur. By adhering to these standards, industries can maximize process efficiency, minimize equipment downtime, and maintain product quality.

Related Concepts in Process Water

Process water is distinct from other water types used in various contexts. To fully understand process water, it’s crucial to define and differentiate between several related concepts:

-

Raw water: Untreated water sourced from rivers, lakes, or wells, containing impurities and contaminants. Process water is often derived from raw water.

-

Potable water: Safe for human consumption, meeting specific quality standards and free from harmful microorganisms and contaminants.

-

Non-potable water: Not suitable for drinking, but may be used for industrial or commercial purposes. Process water often falls into this category.

-

Demineralized water: Water treated to remove dissolved minerals and salts, often used in industries requiring high purity.

-

Deionized water: Water purified to remove nearly all ions, achieving a very high level of purity.

-

Distilled water: Water purified by boiling and condensing, resulting in nearly pure water.

These concepts relate to process water in the following ways:

-

Raw water is the primary source for process water, which undergoes treatment to remove impurities and meet specific quality requirements.

-

Process water may be potable or non-potable, depending on its intended use and the level of treatment required.

-

Demineralized, deionized, and distilled water represent higher purity levels that may be required for specific industrial or scientific applications.

Challenges and Considerations in Process Water Management

Like any resource, process water presents its own set of challenges that require careful consideration. One of the most pressing issues is water scarcity, especially in arid and semi-arid regions. Industries that heavily rely on process water may face disruptions or even operational limitations due to water shortages.

Contamination is another significant concern. Process water can become contaminated through contact with hazardous chemicals, biological contaminants, or other pollutants. This can pose risks to both human health and the environment. To mitigate these risks, it’s essential to implement proper water treatment and monitoring systems to ensure the quality of process water meets regulatory standards.

Environmental regulations play a crucial role in process water management. Governments and regulatory agencies impose strict guidelines to protect water resources and minimize environmental impact. Industries must comply with these regulations by adopting sustainable water management practices, reducing water consumption, and treating wastewater effectively to prevent pollution.

Sustainable water management is paramount for ensuring the long-term availability of process water. Industries should implement water conservation strategies, such as recycling and reuse, to minimize their water footprint. Responsible water use and reducing wastewater discharge can help safeguard water resources for future generations. By embracing sustainable practices, industries can contribute to a circular economy and promote water conservation for the benefit of the environment and society.