Understanding Principal Stress: Key To Material Failure Prediction And Structural Design

Principal stress is the maximum and minimum normal stresses acting perpendicular to each other at a point within a material. It arises due to external loading, capturing the internal stress state. Its significance lies in predicting material failure, designing structures, and analyzing the stability of geological formations. Principal stress axes and directions align with these extreme stresses, facilitating analysis. Mohr’s circle provides a graphical representation of principal stresses and their orientations. Understanding principal stress is crucial for engineers and scientists, enabling them to analyze the behavior of solids under loading and predict their failure mechanisms.

Understanding Principal Stress: A Key to Unraveling Material Behavior

Imagine entering a crowded room, where people are constantly pushing and pulling on each other. The force they exert on one another represents the stress acting within the room. Similarly, within materials, internal stresses arise due to external forces or temperature changes. Understanding these stresses, particularly principal stress, is crucial for engineers and scientists to predict material behavior and ensure structural integrity.

Defining Principal Stress: The Peak and Trough of Internal Forces

Principal stress is the maximum and minimum normal stresses acting perpendicular to each other within a material. Think of it as the most extreme forces pulling and compressing the material. The directions along which these stresses act are known as principal directions, while the coordinate axes aligned with these directions are called principal axes.

The significance of principal stress lies in its ability to reveal the true stress state within a material. By knowing the principal stresses, we can determine the likelihood of material failure, design structures that can withstand external loads, and analyze the stability of soil and rock formations.

Key Concepts Related to Principal Stress

To fully grasp principal stress, it’s essential to understand related concepts:

- Principal Direction: Imaginary lines within the material along which principal stresses operate.

- Principal Axes: Coordinate axes that coincide with the principal directions.

- Mohr’s Circle: A graphical representation of the stress state in a material. Principal stresses are shown as points on the circle, and their orientations can be determined from the angle between the horizontal axis and the line connecting the points.

Principal Stress: Understanding the Key to Internal Stresses in Materials

In the realm of engineering and materials science, understanding the stresses within materials is crucial for predicting their behavior under various loads and environmental conditions. Among the fundamental concepts that elucidates this understanding is principal stress, which unveils the maximum and minimum normal stresses acting perpendicular to each other within a material.

Principal Axes and Directions: Guiding the Stress Landscape

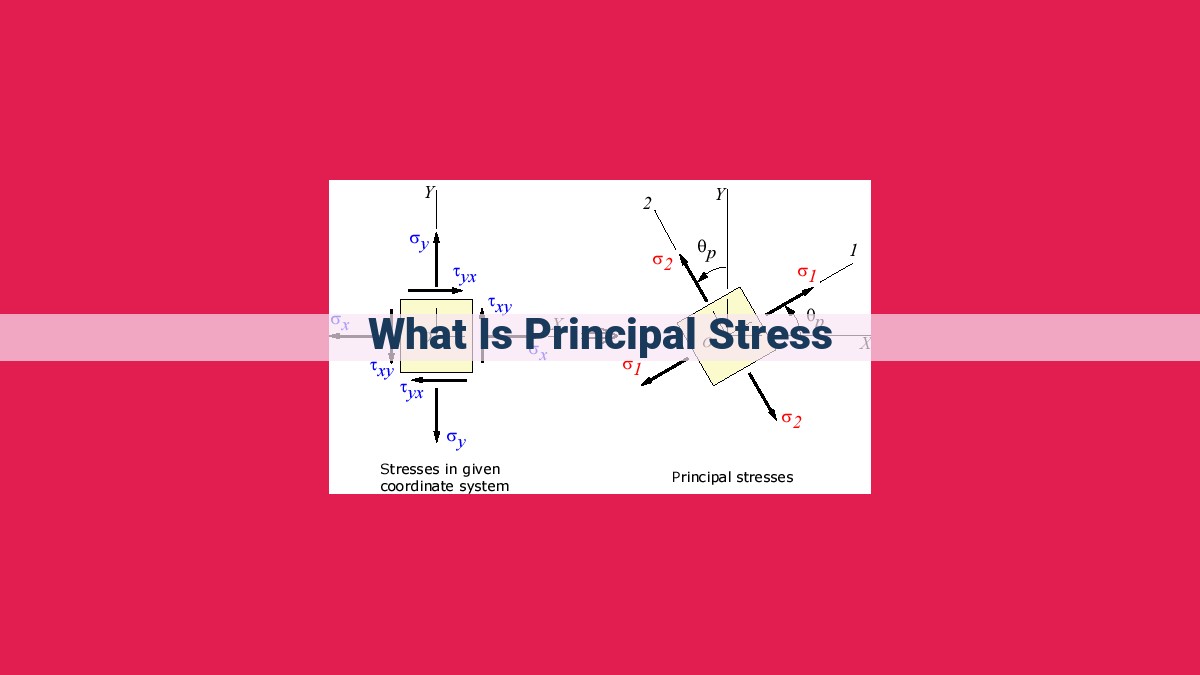

Visualize a block of material subjected to external forces. Within this block, the stress state can be represented by a stress tensor, a mathematical tool that describes the magnitude and direction of stresses acting on the material. Imagine cutting the block into infinitesimally small cubes and examining the stresses on each face. There exist three mutually perpendicular directions where the normal stress is either maximum, minimum, or zero. These directions are called principal directions.

The corresponding axes aligned with these directions are known as principal axes. They provide a reference frame where the stress state can be analyzed and understood in its simplest form. The stresses acting along the principal axes are termed principal stresses.

For a two-dimensional stress state, there exist two principal stresses, σ₁ (maximum) and σ₂ (minimum), acting perpendicular to each other. In three dimensions, there are three principal stresses, σ₁, σ₂, and σ₃, acting along three orthogonal principal axes. These principal stresses provide invaluable insights into the internal stress distribution within a material.

By understanding the principal stresses and directions, engineers and scientists can accurately predict how a material will behave and respond to external loading. This knowledge is particularly critical in designing structures that can withstand the forces they will encounter during their lifespan, ensuring safety and integrity.

Harnessing Principal Stress for Engineering Success

The concept of principal stress has far-reaching applications in engineering and design. By considering the principal stresses and directions, engineers can:

- Analyze failure mechanisms and predict the strength of materials under various loading conditions.

- **Design structures* that can resist external forces by ensuring that the principal stresses remain within acceptable limits.

- **Understand the stability* of soil and rock formations, preventing collapse or failure.

Through a thorough understanding of principal stress and its related concepts, engineers and scientists gain a powerful tool for predicting and controlling the behavior of materials under stress. This understanding is essential for ensuring the safety and reliability of engineered structures and advancing our knowledge of materials science.

Principal Stress: Unlocking the Secrets of Internal Material Stresses

In the realm of materials engineering and structural mechanics, the concept of principal stress holds immense significance. It opens the door to understanding the intricate forces at play within materials under various loading conditions.

Unveiling Principal Directions and Axes

Principal stresses are the maximum and minimum normal stresses that act perpendicular to each other. Imagine a material element subjected to external forces. Within this element, three normal stresses may arise along different axes. However, at specific orientations, the stresses become principal stresses, aligned with the principal directions.

Principal axes represent coordinate axes that are aligned with the principal directions. These axes provide a framework for analyzing the stress state within the material.

Harnessing Mohr’s Circle for Visual Insight

Mohr’s circle is a powerful graphical tool that offers a visual representation of the stress state. It plots the normal and shear stresses acting on different planes within the material. The principal stresses appear as the end points of the diameter of the circle, providing an intuitive understanding of the stress magnitudes and orientations.

Applications of Principal Stress

The concept of principal stress has far-reaching applications in engineering and science:

- Failure Analysis: By determining principal stresses, engineers can predict material failure and identify vulnerable areas in structures.

- Structural Design: Knowing principal stresses enables designers to optimize structures for withstanding external forces and ensuring safety.

- Geotechnical Engineering: In the realm of soil mechanics, principal stresses provide insights into the stability and behavior of soil and rock formations.

Unveiling the Secrets of Principal Stress: Applications in Engineering and Beyond

Understanding the intricacies of internal stresses within materials is crucial for engineers, scientists, and anyone working with solids. Principal stress plays a pivotal role in this understanding, and its practical implications extend far beyond theoretical analysis. In this blog post, we will embark on a journey to explore the applications of principal stress, unlocking its importance in predicting material behavior, designing resilient structures, and ensuring the stability of the natural world.

Analyzing Material Failure and Predicting Behavior

When materials are subjected to external forces, they experience internal stresses. Principal stress provides insights into the maximum and minimum normal stresses acting perpendicular to each other within the material’s cross-section. By analyzing these stresses, engineers can assess the material’s susceptibility to failure and predict its behavior under various loading conditions. This knowledge is essential for designing materials that can withstand extreme loads and preventing catastrophic failures.

Designing Structures that Withstand External Forces

In structural engineering, principal stress plays a vital role in designing buildings, bridges, and other structures that can withstand external forces such as wind, earthquakes, and gravitational loads. By calculating the principal stresses at critical points within the structure, engineers can optimize the design to prevent excessive stress concentrations that could lead to structural collapse. This approach ensures that structures are safe and reliable, protecting lives and property.

Determining Stability of Soil and Rock Formations

Principal stress is also crucial in geotechnical engineering, where it is used to assess the stability of soil and rock formations. By understanding the stress distribution within soil or rock, engineers can determine the risk of landslides, sinkholes, and other geological hazards. This knowledge is essential for planning safe construction projects, ensuring the integrity of infrastructure, and protecting the environment.

Principal stress is a fundamental concept in the field of stress analysis, providing invaluable insights into the behavior of solids under external forces. Its applications extend across various engineering disciplines, from predicting material failure to designing resilient structures and ensuring the stability of the natural world. By understanding principal stress, engineers and scientists can make informed decisions to optimize designs, prevent failures, and ensure the safety and longevity of structures and environments.