Optimize Percent Recovery In Chemical Synthesis: A Guide To Maximizing Efficiency

To find percent recovery, follow these steps: Measure the actual yield of the product experimentally. Calculate the theoretical yield using stoichiometry. Apply the formula for percent recovery: (Actual Yield / Theoretical Yield) x 100%. Understand factors affecting recovery, such as side reactions and purification losses. Optimize the experiment to maximize recovery by minimizing side reactions and improving purification methods. Percent recovery is crucial in chemical synthesis and industrial processes, indicating the efficiency of the reaction.

Percent Recovery: A Measure of Efficiency in Chemical Reactions

In the realm of chemistry, understanding the efficiency of reactions is crucial. Percent recovery serves as a precise measure of this efficiency, offering a quantitative assessment of the amount of desired product obtained from a given reaction.

Definition of Percent Recovery

Percent recovery is a dimensionless quantity expressed as a percentage, indicating the ratio of the actual yield to the theoretical yield of a chemical reaction. It quantifies how much of the anticipated product is successfully isolated and measured.

Significance of Percent Recovery

Determining percent recovery is essential for evaluating the efficacy of a chemical reaction. It provides valuable insights into reaction efficiency, experimental accuracy, and potential errors. A high percent recovery indicates a more efficient reaction, while a low percent recovery suggests areas for improvement in the experimental setup or reaction conditions.

Factors Affecting Percent Recovery

Various factors can influence the percent recovery of a reaction, including:

- Side reactions: Undesired reactions that compete with the main reaction, consuming reactants and reducing product yield.

- Purification losses: Losses incurred during the isolation and purification of the product, due to incomplete precipitation, filtration, or evaporation.

- Measurement errors: Inaccuracies in measuring the mass or volume of reactants and products, leading to deviations from the true values.

How to Calculate Percent Recovery

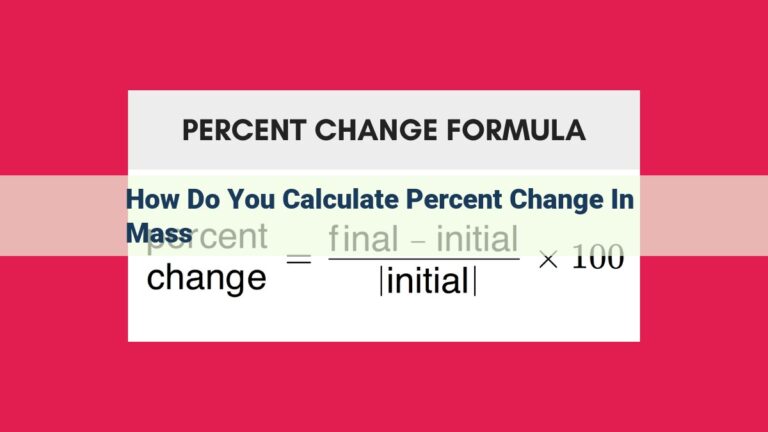

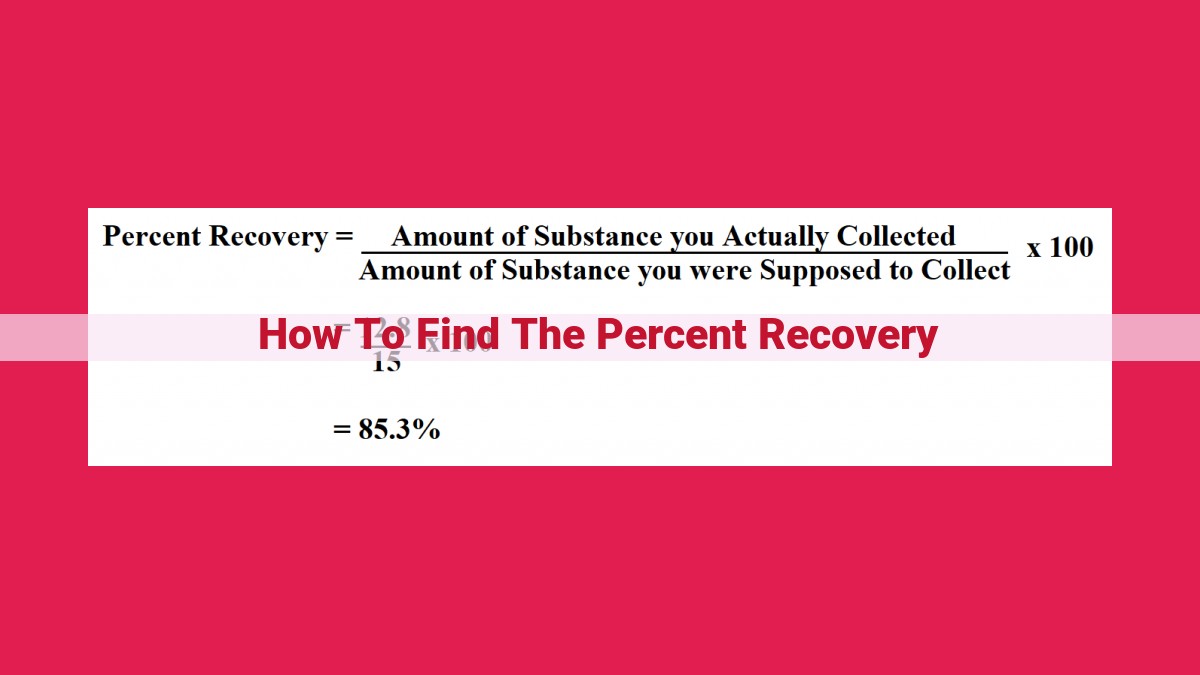

The formula for calculating percent recovery is:

Percent Recovery = (Actual Yield / Theoretical Yield) x 100%

Actual yield refers to the measured mass or volume of the isolated product, while theoretical yield represents the mass or volume of product that would have been obtained if the reaction proceeded with 100% efficiency.

Calculating Percent Recovery: The Key to Understanding Reaction Efficiency

In the world of chemistry, reactions are a fundamental aspect of creating new substances and understanding the behavior of matter. When you conduct a chemical reaction, you strive for optimal efficiency, and one way to measure this efficiency is through percent recovery. This concept plays a pivotal role in determining the yield of a reaction and offers insights into the efficacy of the experimental procedure.

Percent recovery is a measure of the amount of product obtained from a reaction relative to the maximum theoretical yield. It provides a quantitative assessment of how well the reaction proceeds and how effectively you can isolate the desired product. The formula for calculating percent recovery is:

Percent Recovery = (Actual Yield / Theoretical Yield) x 100%

The actual yield is the amount of product you obtain experimentally, while the theoretical yield is the maximum possible amount of product that could be formed based on the stoichiometry of the reaction.

To determine the actual yield, you need to conduct an experiment and measure the mass or volume of the product obtained. This value is then used in the formula to calculate the percent recovery. The theoretical yield, on the other hand, is calculated using stoichiometry, which involves balancing chemical equations to determine the mole ratios between reactants and products. By knowing the moles of reactants used and the stoichiometry of the reaction, you can calculate the maximum amount of product that can be formed.

Understanding percent recovery is crucial for optimizing chemical reactions and maximizing the efficiency of your experiments. It helps you identify areas for improvement, such as minimizing side reactions and optimizing purification methods. By striving for high percent recoveries, you demonstrate a thorough understanding of the chemical processes involved and ensure that you obtain the desired products in the most efficient manner possible.

Determining Actual and Theoretical Yield

When performing a chemical reaction, the actual yield is the amount of product obtained experimentally, while the theoretical yield is the maximum amount of product that could be obtained based on the stoichiometry of the reaction.

Factors Affecting Actual Yield

Several factors can influence the actual yield of a reaction, including:

- Side reactions: Unwanted reactions that occur alongside the desired reaction, reducing the yield of the desired product.

- Loss during purification: Impurities present in the reaction mixture can make it challenging to isolate the pure product, resulting in a lower actual yield.

- Inaccuracy in measurement: Errors in measuring the reactants or products can lead to inaccurate yield calculations.

Calculating Actual Yield

To determine the actual yield, the following steps are followed:

- Measure the mass or volume of the purified product.

- Convert the measured quantity to moles using its molar mass.

- Calculate the percentage yield using the formula:

Percent yield = (Actual yield / Theoretical yield) x 100%

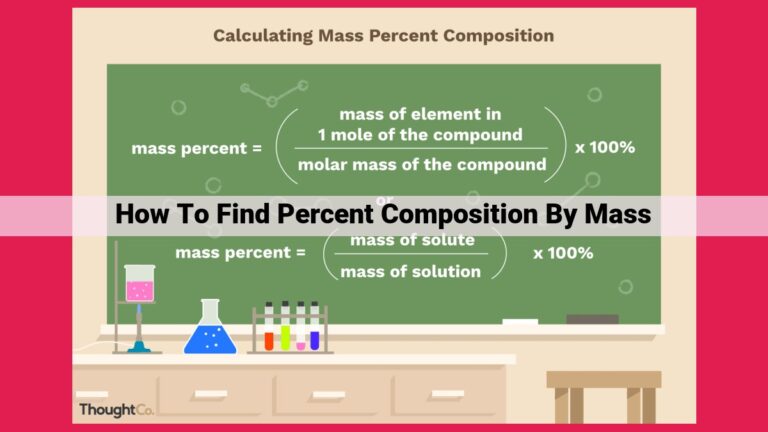

Calculating Theoretical Yield

The theoretical yield is calculated based on the stoichiometry of the reaction. Stoichiometry is the study of the quantitative relationships between reactants and products in a chemical reaction. The balanced chemical equation for the reaction provides the mole ratio between the reactants and products.

To calculate the theoretical yield:

- Determine the limiting reactant, which is the reactant that is completely consumed in the reaction.

- Use the mole ratio to calculate the maximum amount of product that can be formed from the limiting reactant.

- Convert the moles of product to mass or volume using its molar mass or density.

Factors that Diminish Percent Recovery

In the pursuit of maximizing percent recovery, it’s crucial to be cognizant of the obstacles that may hinder this efficiency measure. These challenges, lurking in the shadows of chemical reactions, can stealthily reduce the yield, leaving you with less of the desired product.

Adversaries of Percent Recovery

-

Side Reactions: These uninvited guests compete with the intended reaction, diverting precious reactants and leading to the formation of unwanted byproducts. These sneaky side reactions are like mischievous pixies, stealing your reagents and leaving you with a diminished yield.

-

Purification Loss: Even when the desired product has emerged victorious from the chemical battlefield, the journey is not over. Purification methods, intended to isolate the target compound, can sometimes be like clumsy knights, inadvertently discarding some of the precious product along the way. Losses during extraction, crystallization, or distillation can chip away at your percent recovery.

Countering the Challenges

Understanding the factors that can jeopardize percent recovery is half the battle. The other half lies in developing strategies to mitigate their impact. By employing techniques that minimize side reactions and optimize purification methods, you can increase your chances of achieving a high percent recovery.

How to Calculate and Optimize Percent Recovery in Chemical Reactions

What is Percent Recovery?

Percent recovery is a crucial parameter in chemistry, quantifying the efficiency of a chemical reaction. It measures the amount of desired product obtained from a reaction compared to the theoretical maximum yield. Understanding percent recovery helps chemists evaluate reaction success and identify areas for improvement.

Calculating Percent Recovery

To calculate percent recovery, we use the formula:

Percent Recovery = (Actual Yield / Theoretical Yield) x 100%

- Actual Yield: The actual amount of product obtained from the experiment, measured in grams or moles.

- Theoretical Yield: The maximum amount of product that can be obtained from the reaction, predicted using stoichiometry.

Measuring Actual and Theoretical Yield

Actual Yield: Factors like incomplete reactions and purification loss can affect the actual yield. Experimental methods are used to measure the actual yield of the product.

Theoretical Yield: Stoichiometry, the study of chemical proportions, assists in calculating the theoretical yield based on the balanced chemical equation of the reaction.

Factors Affecting Percent Recovery

Challenges such as side reactions, incomplete reactions, purification losses, and inaccurate measurements can impact percent recovery. By optimizing reaction conditions and purification methods, chemists can minimize these factors and enhance recovery.

Step-by-Step Guide to Finding Percent Recovery

- Conduct the experiment: Perform the chemical reaction and follow the experimental procedure carefully.

- Measure actual yield: Determine the actual amount of product obtained after the reaction and purification.

- Calculate theoretical yield: Use stoichiometry to calculate the theoretical maximum yield.

- Apply percent recovery formula: Plug the values of actual and theoretical yield into the percent recovery formula.

Optimizing Percent Recovery

- Minimizing side reactions: Employ selective catalysts or adjust reaction conditions to suppress unwanted reactions.

- Improving purification methods: Optimize extraction, filtration, and recrystallization techniques to maximize product purity.

- Ensuring accurate measurements: Calibrate equipment and use reliable methods to minimize errors in yield measurements.

Applications of Percent Recovery

Percent recovery finds application in various fields, including:

- Chemical synthesis: Monitoring reaction efficiency and identifying areas for improvement in synthesis protocols.

- Industrial processes: Assessing the efficiency of large-scale chemical manufacturing processes.

- Environmental monitoring: Determining the recovery rate of chemicals in extraction or remediation processes.

Optimizing Percent Recovery: Strategies for Enhanced Chemical Efficiency

Maximizing the efficiency of chemical reactions is crucial for various scientific and industrial endeavors. Percent recovery serves as a valuable metric for evaluating the effectiveness of these reactions. By understanding the factors that influence percent recovery, researchers and practitioners can optimize their processes to achieve higher yields and reduce waste.

One key strategy for optimizing percent recovery involves minimizing side reactions. Side reactions are unintended chemical processes that compete with the desired reaction, diverting reactants away from the main pathway. By employing selective catalysts, optimizing reaction conditions (e.g., temperature, pressure), and purifying starting materials, the incidence of side reactions can be significantly reduced.

Another important aspect is optimizing purification methods. Once the desired product is formed, it often needs to be purified to remove impurities and achieve the desired quality. Techniques such as distillation, chromatography, and crystallization can be employed to effectively isolate the product. By carefully optimizing these methods, the loss of product during purification can be minimized, leading to higher percent recoveries.

Additional strategies for optimizing percent recovery include:

-

Using appropriate solvents and reagents: The choice of solvents and reagents can influence the reaction rate, selectivity, and yield. Experimentation and careful selection are necessary to identify the optimal combination for a given reaction.

-

Monitoring reaction progress: Regularly monitoring the reaction progress allows for timely adjustments to reaction conditions if necessary. This helps prevent over-reaction or the formation of unwanted byproducts.

-

Employing scale-up and optimization techniques: Once a reaction has been optimized on a small scale, it often needs to be scaled up for larger-scale production. Proper scale-up techniques and further optimization are essential to maintain high percent recoveries during industrial-scale manufacturing.

By implementing these strategies, researchers and practitioners can effectively optimize percent recovery, leading to improved chemical efficiency, reduced waste, and enhanced overall process effectiveness.

Percent Recovery: Its Importance in Various Fields

In the realm of chemistry, percent recovery is a crucial metric that evaluates the efficiency of chemical reactions. It holds profound implications in numerous fields, including chemical synthesis, industrial processes, and beyond.

Chemical Synthesis

In chemical synthesis, percent recovery is a measure of the efficiency with which a desired product is obtained. It is calculated by comparing the actual yield, or the amount of product actually obtained, to the theoretical yield, or the maximum amount that could have been produced based on stoichiometry. A high percent recovery indicates a more efficient reaction, while a low percent recovery suggests areas for improvement.

Industrial Processes

In industrial processes, percent recovery is equally important for maximizing production efficiency. For instance, in the production of pharmaceuticals, high percent recovery ensures that valuable active ingredients are not lost during synthesis and purification. This optimization leads to cost savings and increased profitability.

Environmental Science

Percent recovery also plays a vital role in environmental science. In wastewater treatment, for example, it gauges the efficiency of removing pollutants from wastewater. A high percent recovery indicates that more pollutants are being removed, resulting in cleaner and safer discharge into the environment.

Research and Development

In research and development, percent recovery is a key parameter for optimizing new chemical processes. By maximizing percent recovery, researchers can minimize waste and reduce costs associated with原料and labor. This optimization accelerates the development and commercialization of new products.

Percent recovery serves as an indispensable metric in various fields, providing valuable insights into process efficiency, production costs, environmental impact, and research outcomes. By understanding the concept of percent recovery and employing strategies to optimize it, professionals can enhance the efficiency of chemical reactions, maximize production yields, and contribute to sustainable practices and advancements in science and industry.