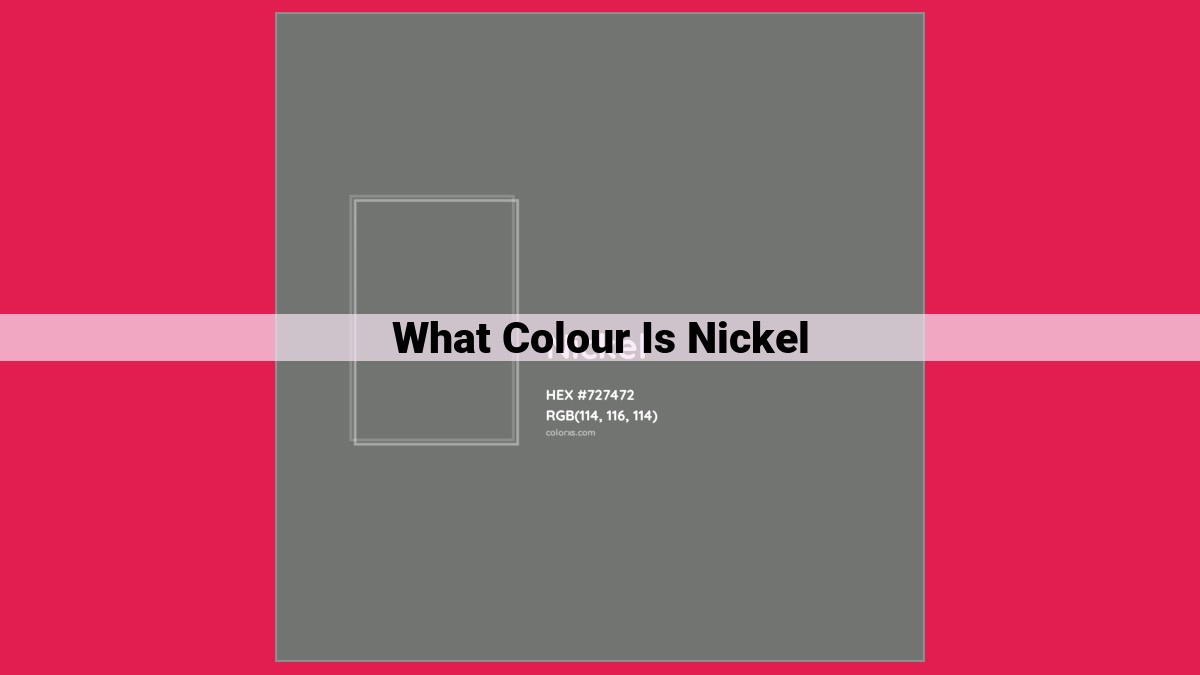

Nickel: A Silvery-White Metal With A Luster Like Polished Silver

Nickel, a metal renowned for its silvery-white color, exhibits a lustrous shine akin to polished silver. Its polished surface reflects light, giving it a bright, silvery-white hue distinct from other metals. However, over time, nickel may tarnish to form a yellowish-green layer due to oxidation.

- Define nickel as a metal and mention its primary color (silvery-white).

Unveiling the Silvery Secrets of Nickel: A Timeless Metal

In the realm of metals, nickel stands out with its gleaming allure and unique characteristics. Silvery-white, it embodies the essence of polished silver, inviting admiration with its lustrous surface. Its name, derived from German mythology’s mischievous spirit, aptly reflects its fascinating properties.

Nickel’s metallic luster is a captivating sight. Resembling polished silver, its shiny, reflective nature adds a touch of radiance to any object. Its silvery-white hue distinguishes it from other similar metals, making it a popular choice for decorative purposes and jewelry making.

Nickel’s Enchanting Metallic Charm

In the realm of metals, nickel stands out with its captivating allure. It is a silvery-white metal that gleams like polished silver, reflecting light in a mesmerizing dance. Its metallic lustre is reminiscent of a shimmering lake under a moonlit sky, captivating the eye with its radiant brilliance.

Nickel’s silvery sheen sets it apart from its metallic counterparts. Unlike copper’s warm glow or iron’s dull grey, nickel possesses an unparalleled brilliance that makes it a favorite for decorative and functional applications. Its polished surfaces mirror the world around it, creating illusions and enhancing the aesthetics of everything it adorns.

This unique metallic lustre is not merely a superficial charm. It is a testament to nickel’s inherent properties. Nickel’s high reflectivity and low emissivity make it an exceptional conductor of heat and an effective barrier against corrosion. Its shiny surface reflects sunlight, keeping objects cool even under intense heat. And its resistance to tarnishing ensures that its brilliance endures over time, especially in demanding environments.

Nickel’s Polished Silvery-White Hue: A Distinctive Charm

Nickel, a lustrous metal, boasts a shimmering silvery-white hue that sets it apart from other metals. Its polished surface reflects light with a brilliant gleam, reminiscent of finely polished silver. This distinctive coloration is due to the metal’s high reflectivity, which arises from its smooth and uniform crystalline structure.

Nickel’s silvery-white color is remarkably stable, resisting tarnishing and discoloration for extended periods. Unlike other metals, such as iron or copper, which develop a dull or oxidized appearance over time, nickel maintains its pristine brilliance. This exceptional color retention makes it an ideal choice for cosmetic applications, such as jewelry, decorative items, and architectural accents.

Furthermore, nickel’s bright and reflective nature enhances its aesthetic appeal. Its gleaming surface creates an eye-catching contrast with other materials, making it a popular choice for use in fashion accessories, automotive components, and electronic devices. The unique silvery-white hue of nickel adds a touch of elegance and sophistication to any design.

Nickel’s Enigmatic Color Transformation: From Silver to Yellowish-Green

In the realm of metals, nickel stands out with its captivating color that metamorphoses from a lustrous silvery-white to a dull yellowish-green. This transformation, known as tarnishing, is a dance between nickel, oxygen, and time.

Tarnishing: The Dance of Oxidation

Like all metals, nickel has an affinity for oxygen. When exposed to the air, oxygen molecules interact with nickel atoms, forming a thin layer of nickel oxide. This oxide film acts as a barrier, protecting the underlying metal from further oxidation.

However, the oxide film is not impermeable. Over time, moisture and other environmental factors can penetrate the film, allowing oxygen to reach the fresh metal beneath. As more oxide forms, the protective barrier thickens, resulting in a noticeable color change.

Factors Influencing Tarnishing

The rate and extent of nickel tarnishing depend on several factors:

- Temperature: Higher temperatures accelerate oxidation.

- Humidity: Moist environments favor faster tarnishing.

- Exposure to pollutants: Acids and other corrosive substances can exacerbate tarnishing.

- Surface finish: Polished surfaces tarnish more slowly than rough ones.

From Lustrous to Lackluster: The Yellowish-Green Hue

As the oxide layer thickens, the once-bright silvery-white nickel transforms into a dull yellowish-green. This color change results from the interference of light with the oxide film. Different wavelengths of light are reflected and absorbed differently, leading to the characteristic yellowish-green hue.

While tarnishing affects nickel’s appearance, it does not significantly alter its structural properties. However, extended exposure to harsh environments can eventually compromise the metal’s integrity.

Conductive Properties of Nickel: A Pathway for Electrical Flow

Throughout the realm of metals, nickel stands out as a veritable champion of electrical conductivity. Its exceptional ability to facilitate the flow of electrons has propelled it to the forefront of myriad applications, from powering our homes to powering our imaginations.

Nickel’s conductivity stems from its unique atomic structure, which features delocalized electrons. These electrons are not bound to any particular atom, allowing them to move freely throughout the metal’s lattice. This mobile army of electrons creates a conductive pathway, enabling the effortless transfer of electrical current.

Nickel’s high conductivity makes it an ideal choice for a wide range of electrical components, including:

-

Batteries: Nickel is a key ingredient in many types of batteries, such as nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries. These batteries rely on nickel’s ability to store and release electrical energy through reversible electrochemical reactions.

-

Wires: Nickel is also extensively used in the production of electrical wires and cables. Its excellent conductivity ensures efficient transmission of electrical signals over long distances, making it indispensable for everything from power lines to telecommunications networks.

Nickel’s conductivity is a testament to its versatility and practicality. From powering our electronic devices to illuminating our cities, nickel continues to play a critical role in the electrical infrastructure that underpins our modern world.

The Malleability of Nickel: A Versatile Metal with Diverse Applications

Nickel, a silvery-white metal, boasts remarkable malleability, allowing it to be easily shaped and molded without breaking. This inherent property makes nickel a highly sought-after material in a wide range of industries.

Malleability refers to the ability of a substance to undergo plastic deformation without cracking or tearing. Nickel’s exceptional malleability allows it to be shaped into various forms, including sheets, wires, and complex parts.

In the automotive industry, nickel’s malleability is harnessed to produce a wide range of components. Nickel-coated steel is used in the construction of car bodies, providing a durable and corrosion-resistant surface. Nickel-based alloys are also utilized in spark plugs, ensuring reliable ignition and optimal engine performance.

The construction sector also relies heavily on nickel’s malleability. Nickel-plated fixtures, such as doorknobs and railings, offer both durability and aesthetic appeal. Nickel-coated steel is employed in the fabrication of roofing and siding materials, providing excellent resistance to weathering and wear.

Jewelry making is another industry that benefits from nickel’s malleability. Nickel is often alloyed with other metals to create white gold, a popular material for wedding bands and other fine jewelry. Nickel’s strength and durability make it an excellent choice for rings and other pieces that experience regular wear and tear.

Beyond these industries, nickel’s malleability finds applications in electronics, chemical processing, and aerospace. Nickel-based alloys are used in the production of batteries, electronics components, and high-performance engines. Its ability to be shaped into intricate forms makes it ideal for specialized components and precision instruments.

The malleability of nickel is a key factor in its widespread utility. This versatile metal can be effortlessly molded into complex shapes, making it suitable for a diverse array of applications. From automobiles to jewelry, construction to electronics, nickel’s malleability empowers industries to produce durable, reliable, and aesthetically pleasing products.

Nickel: A Versatile Metal with Exceptional Ductility

As we delve into the captivating world of metals, let’s focus our attention on the remarkable element known as nickel. This silvery-white wonder has captivated scientists and engineers alike with its unique properties, including exceptional ductility.

Drawing the Line with Nickel’s Malleability

Nickel’s malleability allows it to be shaped and manipulated into various forms without breaking. This malleable nature makes it ideal for applications where shaping is crucial, such as sheet metalworking and jewelry making. Flexible and adaptable, nickel can be easily hammered, rolled, and pressed into intricate designs, giving rise to beautiful and functional objects.

Unveiling the Strength of Ductility

Beyond its malleability, nickel also exhibits extraordinary ductility. This property enables nickel to be drawn into thin wires or threads without snapping. This remarkable characteristic has made nickel indispensable in manufacturing and construction.

In the realm of manufacturing, nickel wires find their niche in the production of electronic components, such as resistors and capacitors. These delicate wires facilitate the efficient flow of electricity, playing a vital role in the functioning of countless devices.

Nickel’s ductility also shines in the construction industry. Reinforcement bars made of nickel-containing steel are the backbone of many structures, including bridges and buildings. These bars provide unyielding strength and resilience, ensuring the longevity and structural integrity of these towering testaments to human ingenuity.

Nickel’s ductility is an invaluable asset in various fields, empowering engineers and manufacturers to craft intricate products and construct durable structures. Its ability to be shaped, drawn, and manipulated makes it a versatile and indispensable material in the modern world.

Nickel’s Magnetic Charisma

In the realm of metals, nickel stands out as a master of magnetism. Unlike its non-magnetic counterparts, nickel possesses an alluring ability to attract and be attracted by magnetic forces. This magnetic charm stems from the arrangement of its electrons, which align in a specific pattern creating tiny magnets within the metal.

As these internal magnets interact, they amplify each other’s strength, resulting in the overall magnetic properties of nickel. This magnetic prowess makes nickel a valuable ally in a wide range of applications, from everyday objects to advanced technologies.

One notable use of nickel’s magnetism is in the production of magnets themselves. By subjecting nickel to intense magnetic fields, its internal magnets become even more aligned, creating powerful permanent magnets. These magnets find their way into a myriad of devices, including compasses, electric motors, and MRI machines.

Moreover, nickel’s magnetic properties play a crucial role in the performance of batteries. In rechargeable batteries, nickel is often combined with other metals to form alloys that exhibit strong magnetic properties. These alloys enhance the battery’s ability to store and release electrical energy efficiently, making them ideal for powering portable devices and electric vehicles.

Nickel’s High Melting Point: A Test of Strength

In the realm of metals, nickel stands out as a true champion of heat resistance. With a melting point of an impressive 1,455 degrees Celsius (2,651 degrees Fahrenheit), it dwarfs the melting points of common metals like iron and aluminum.

This remarkable property has earned nickel a special place in industries where intense heat is a constant companion. In the aerospace sector, it serves as a crucial component in jet engines and rockets, where it withstands the scorching temperatures generated by combustion. In the automotive industry, nickel alloys help strengthen pistons and exhaust systems, enabling engines to perform at their peak under demanding conditions.

Nickel’s high melting point also makes it an ideal material for chemical processing equipment. It can withstand the corrosive effects of harsh chemicals and high temperatures, ensuring the safe and efficient handling of hazardous substances.

Nickel: A Metal of Exceptional Resistance

Amidst the vast array of metals, nickel stands out with its unique silvery-white luster. Its malleability and ductility make it a versatile material for various applications. However, one of nickel’s most remarkable qualities lies in its exceptional resistance to corrosion.

Corrosion, the bane of many metals, occurs when they react with substances in the environment, leading to rust, decay, and deterioration. Nickel, however, laughs in the face of corrosion. Its strong atomic bonds and protective oxide layer make it highly resistant to atmospheric oxygen, water, and even corrosive chemicals.

This remarkable corrosion resistance makes nickel an ideal material for marine environments, where exposure to saltwater and harsh conditions is inevitable. Ships, boats, and other marine structures crafted from nickel alloys withstand the corrosive onslaught of the ocean, ensuring longevity and safety.

Beyond marine applications, nickel’s anti-corrosion properties also extend to industrial environments, chemical processing, and harsh outdoor settings. In these demanding realms, nickel alloys endure the test of time, maintaining their strength and integrity even under extreme conditions.

Nickel’s exceptional corrosion resistance stems from the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing oxygen, moisture, and other corrosive agents from penetrating the metal. As a result, nickel effectively resists rust and decay, preserving its structural integrity and ensuring long-lasting performance.

Indeed, nickel’s corrosion resistance is a testament to its unique properties that make it a valuable metal in various industries, where reliability and durability are paramount. Whether guarding against the relentless onslaught of marine environments or enduring the corrosive challenges of industrial settings, nickel stands as a beacon of resilience, ensuring the longevity of structures and equipment.

Nickel Allergies: A Common Ailment

Despite its widespread use, nickel can also be a source of discomfort for some individuals. Nickel allergies are a common skin condition that affects a significant portion of the population. Exposure to nickel can trigger an allergic reaction, leading to contact dermatitis.

Contact dermatitis is a type of skin irritation that develops when the skin comes into contact with an allergen. In the case of nickel allergies, the allergen is nickel itself. Nickel is found in a variety of everyday objects, including jewelry, coins, keys, and even clothing. When an individual with a nickel allergy comes into contact with these objects, it can cause the skin to become red, itchy, and inflamed. In severe cases, blisters and swelling may also occur.

Prevalence and Symptoms of Nickel Allergies

Nickel allergies are one of the most common types of contact allergies, affecting up to 10% of the population. Women are more likely to develop a nickel allergy than men, primarily due to their increased exposure to nickel-containing jewelry. Symptoms of a nickel allergy can vary from mild to severe, and may include:

- Redness and itching

- Blisters and swelling

- Skin thickening and discoloration

- Rash or eczema

Diagnosis and Treatment of Nickel Allergies

Diagnosing a nickel allergy involves a simple patch test. During the test, a small amount of nickel is applied to the skin and monitored for a reaction. If the skin develops a reaction, it indicates a nickel allergy.

Treating a nickel allergy involves avoiding exposure to nickel. Individuals with a nickel allergy should avoid wearing jewelry, clothing, and other objects that contain nickel. Additionally, they should be mindful of foods that may contain nickel, such as chocolate, canned fruits and vegetables, and shellfish. Avoiding exposure to nickel can help prevent allergic reactions and skin irritation.

Nickel allergies are a common ailment that can cause discomfort and skin irritation for many individuals. Understanding the symptoms and prevalence of nickel allergies is crucial for those who may be affected by this condition. If you suspect that you have a nickel allergy, it is essential to seek professional advice for proper diagnosis and treatment. By avoiding exposure to nickel, individuals with allergies can manage their symptoms and improve their skin health.