Title: Understanding The Remarkable Properties And Applications Of Metals

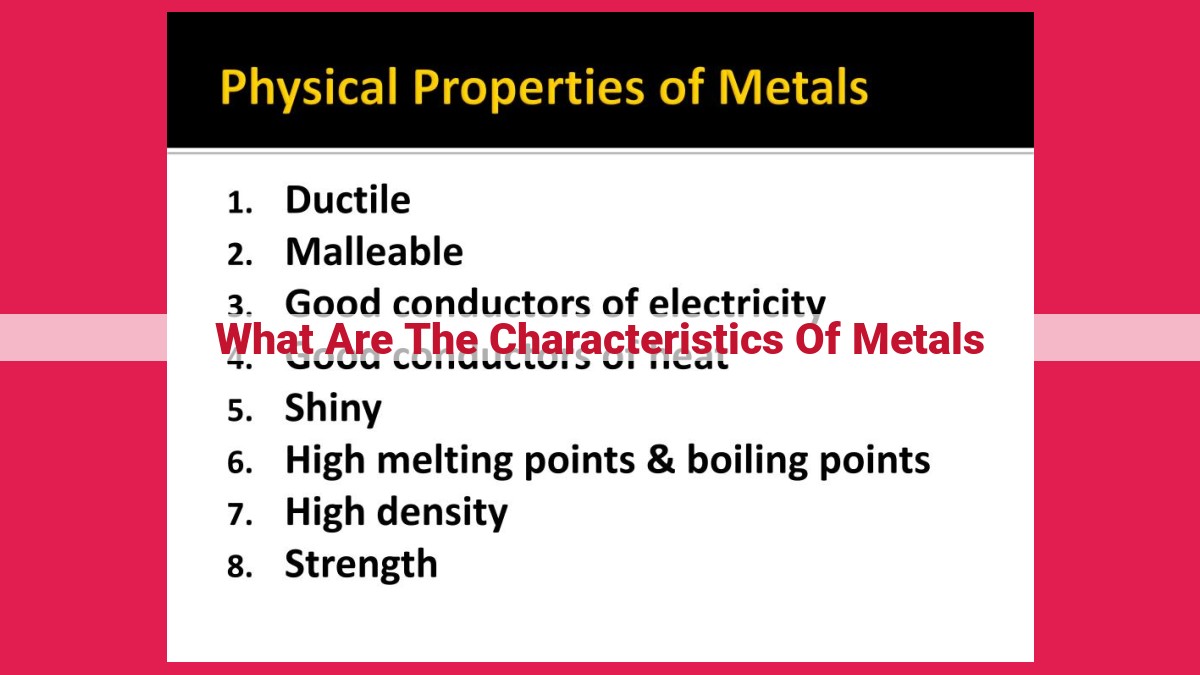

Metals possess a distinctive lustrous shine due to their ability to reflect light. They are highly malleable and ductile, allowing them to be reshaped without breaking. Metals exhibit excellent conductivity, facilitating efficient heat and electricity transfer. They produce resonant sounds, contributing to their use in musical instruments. Density varies among metals, impacting their weight and buoyancy. Härte, Stärke und Dehnbarkeit unterscheiden sie, wobei harte Metalle für Haltbarkeit und weiche für Verformbarkeit geeignet sind. Schmelz- und Siedepunkte bestimmen ihre Eignung für industrielle Prozesse und Anwendungen.

Lustre: A Distinctive Radiance

Throughout history, metals have captivated humanity with their lustrous surfaces. This inherent shine is a consequence of their atomic structure, where electrons flow effortlessly across their surfaces, reflecting light and imparting a distinctive radiance.

The aesthetic appeal of lustrous metals is undeniable. From the shimmering gold of ancient artifacts to the gleaming chrome of modern automobiles, metals have played a central role in human adornment and artistic expression. Their reflective qualities lend an air of elegance and sophistication, making them a timeless choice for jewelry, silverware, and decorative objects.

In addition to their aesthetic value, the lustre of metals has practical significance. It facilitates light reflection, enhancing visibility and safety in various applications. For instance, the shiny surfaces of traffic signs and streetlamps help drivers navigate roads at night. Similarly, the lustrous finish of cookware helps reflect heat, enabling efficient cooking and reducing energy consumption.

Malleability and Ductility: The Flexible and Deformable Nature of Metals

In the realm of materials science, metals stand out for their exceptional ability to undergo transformations without compromising their integrity. This remarkable malleability and ductility empower metals to assume diverse shapes, enabling their use in a myriad of applications.

Malleability, the property of metals that allows them to be flattened or rolled into thin sheets without rupturing, makes them indispensable for crafting items such as aluminum foil and sheet metal roofing. Their ductility, on the other hand, enables them to be drawn into wires or threads, as seen in copper wires and surgical sutures.

The malleability and ductility of metals stem from their atomic structure. Metals typically possess a face-centered cubic or body-centered cubic crystal structure, which allows their atoms to slide past each other during deformation. This atomic rearrangement allows the metal to conform to new shapes without breaking.

These exceptional properties make metals versatile materials for a wide range of industries. In construction, they are used for framing, roofing, and cladding. In manufacturing, they are employed in the production of car bodies, appliances, and electronic components. In art and design, they inspire sculptures, jewelry, and decorative objects.

The malleability and ductility of metals are truly remarkable properties that have revolutionized human ingenuity. They have enabled us to craft everything from skyscrapers to microchips, transforming the world around us in countless ways.

Conductivity: The Gateway to Efficient Energy Flow

In the realm of materials, metals stand out for their exceptional ability to transfer both heat and electricity. This remarkable property, known as conductivity, plays a pivotal role in a myriad of applications that shape our daily lives.

The electrons within metals are loosely bound, allowing them to move freely throughout the material. This electron mobility facilitates the efficient conduction of heat, enabling metals to act as effective thermal conductors. From cooking utensils that distribute heat evenly to radiator systems that warm homes, metals excel in transferring thermal energy.

Similarly, the ability of metals to transfer electrical charge makes them essential for transmitting and utilizing electricity. Conductors like copper form the backbone of electrical circuits, allowing electrons to flow smoothly and power devices such as computers, appliances, and lighting systems.

The exceptional conductivity of metals makes them invaluable for applications where efficient heat and electricity transfer is paramount. In heating and cooling systems, metals facilitate the rapid exchange of thermal energy, ensuring comfort and energy efficiency. In electrical engineering, metals enable the transmission of electricity with minimal losses, ensuring reliable and efficient power distribution.

Sonority: The Melodious Nature of Metals

Throughout history, metals have not only served practical purposes but have also delighted our ears with their unique acoustic properties. From the haunting sounds of ancient bells to the soaring notes of modern musical instruments, metals possess an inherent sonority that has captured the imagination of musicians and sound engineers alike.

Metals’ ability to produce resonant sounds stems from their density and elasticity. When struck or vibrated, metal atoms move back and forth in a regular pattern, creating sound waves. The density of the metal affects the pitch of the sound, with denser metals producing lower tones. The elasticity of the metal determines the timbre, or distinctive sound quality, of the instrument.

This melodious nature of metals has made them indispensable in the creation of musical instruments. The shimmering notes of brass instruments, such as trumpets and trombones, are a testament to the sonority of copper and its alloys. The clear, bell-like tones of glockenspiels and xylophones are produced by the vibration of aluminum and steel bars. Even the humble cowbell, with its distinctive “clang,” owes its sound to the resonant properties of iron.

Beyond musical instruments, the sonority of metals is harnessed in a variety of other applications. Sound enhancement devices, such as resonant chambers and acoustic panels, use metal to amplify and shape sound waves. Metal plates are also used in lithophones, instruments that produce musical notes when struck with a mallet.

The sonorous nature of metals is a testament to their versatility and the interplay between their physical properties and acoustic characteristics. From the gentle tinkling of a wind chime to the thunderous roar of a bass drum, the ability of metals to produce resonant sounds has left an indelible mark on the world of music and sound.

Density: Weighty or Buoyant

In the realm of metals, density reigns supreme as a crucial characteristic that governs their weight and buoyancy. This remarkable property determines whether a metal will sink or float in water.

Metals with high densities, like lead and gold, find their niche in applications where weight is a priority. These metals serve as sturdy weights for scales and counterbalance in machines. Their substantial weight also makes them ideal for anchors, ensuring that vessels remain securely moored in place.

Conversely, metals with low densities, such as aluminum and titanium, defy gravity with their buoyancy. These lightweight wonders are sought after in the aerospace industry, where every ounce shaved off the weight of an aircraft translates into increased fuel efficiency. Their buoyancy also makes them perfect for boat hulls and pontoons, enabling them to effortlessly float upon the water’s surface.

Understanding the density of metals is not merely an academic pursuit; it’s a practical tool that guides engineers, designers, and architects in their transformative creations. By carefully selecting metals based on their density, we harness their unique properties to shape our world.

Hardness: Strength or Pliability

Metals possess a unique characteristic known as hardness, which refers to their resistance to deformation and permanent shape changes. This property plays a critical role in determining the suitability of metals for various applications and industries.

Metals are classified as either hard or soft based on their hardness. Hard metals, such as steel and titanium, have strong interatomic bonds that make them highly resistant to bending, denting, and scratching. Their exceptional strength enables them to endure external forces without losing their structural integrity.

Soft metals, on the other hand, like aluminum and lead, have weaker atomic bonds and are easily deformed. They can be manipulated and shaped with relative ease, making them ideal for applications requiring pliability. For instance, the malleability of aluminum allows it to be formed into thin sheets and wires, while the ductility of copper enables it to be drawn into intricate wires.

The hardness of a metal is a critical factor in determining its suitability for specific purposes. Hard metals are often used in construction, automotive parts, and tools that require exceptional strength and durability. Soft metals, on the other hand, find applications in electrical components, decorative items, and packaging materials where pliability and ease of manipulation are desired.

Melting and Boiling Points: Temperature Transitions

Every metal possesses a unique set of properties that define its characteristics and applications. Among these properties, melting point and boiling point hold immense significance in determining the suitability of metals for various industrial processes and applications.

The melting point of a metal is the temperature at which it transitions from a solid to a liquid state. This property is crucial in metalworking, casting, and welding operations. For instance, metals with low melting points, like lead and aluminum, are ideal for casting intricate shapes and components. On the other hand, metals with high melting points, such as tungsten and titanium, are used in applications where extreme heat resistance is required, like aerospace and high-temperature machinery.

The boiling point of a metal, on the other hand, is the temperature at which it transforms from a liquid to a gaseous state. This property is equally important in various industries, such as metallurgy, chemical processing, and energy production. Metals with high boiling points, such as mercury and cesium, are used in high-temperature applications, like nuclear reactors and heat exchangers. Conversely, metals with low boiling points, such as gallium and cadmium, are employed in low-temperature processes, like electronics and cryogenics.

Understanding the melting and boiling points of metals is essential for optimizing their use in different applications. By carefully selecting metals based on their temperature transitions, manufacturers can ensure the longevity, efficiency, and safety of their products and processes.