Maximize Reaction Efficiency: Understand Percent Recovery

Percent recovery, a measure of reaction efficiency, is calculated by dividing the actual yield obtained in an experiment by the theoretical yield, multiplied by 100%. The actual yield represents the amount of product collected, while the theoretical yield is the maximum possible product based on stoichiometry. Percent recovery is influenced by factors like side reactions, reactant purity, and measurement errors. Optimization techniques, including optimizing reaction conditions, using high-purity reactants, and ensuring accurate measurements, can improve recovery rates.

Understanding Actual Yield: The Measurable Reality

In the realm of experimentation, the actual yield stands as a tangible measure of your efforts. It represents the amount of product you physically obtain from your chemical reaction. This real-world yield contrasts with the theoretical yield, an idealized value that assumes perfect conditions.

Like its synonyms experimental yield, observed yield, and collected yield, the actual yield reflects the actual amount of product you’ve successfully produced. It’s the culmination of your experimental setup, technique, and the unpredictable factors inherent in any scientific endeavor.

By grasping the concept of actual yield, you’ll gain a deeper understanding of the nature of chemical reactions and the variables that can influence their outcome. This knowledge will empower you to optimize your experiments and achieve better results.

Defining Theoretical Yield: The Maximum Potential

In the realm of chemistry, the concept of theoretical yield plays a crucial role in understanding the efficiency of chemical reactions. It represents the maximum amount of product that can be obtained from a given set of reactants, based on the stoichiometry of the balanced chemical equation. In other words, theoretical yield is the yield calculated from the chemical equation, assuming 100% efficiency.

Theoretical yield serves as a benchmark against which the actual yield of a reaction can be compared. By calculating the percent recovery, chemists can assess how close their experimental results came to the maximum potential. This information is invaluable for optimizing reaction conditions, troubleshooting inefficiencies, and improving product quality.

Synonyms for theoretical yield include calculated yield, predicted yield, and maximum yield. These terms all refer to the same concept: the theoretically possible amount of product that can be obtained from a given reaction. Understanding the difference between theoretical yield and actual yield is essential for interpreting experimental data and making informed decisions about chemical processes.

Calculating Percent Recovery

- Equation: (Actual Yield / Theoretical Yield) x 100%

- Interpretation: Measure of reaction efficiency

Calculating Percent Recovery: A Measure of Reaction Efficiency

In the realm of chemistry, the yield of a reaction is a crucial parameter that quantifies the actual amount of product obtained from a chemical transformation. But how do we determine if our reaction was successful? That’s where percent recovery comes into play.

Percent recovery provides a numerical measure of how well our reaction performed compared to its theoretical potential. It’s a testament to the efficiency of our reaction and helps us identify areas for improvement.

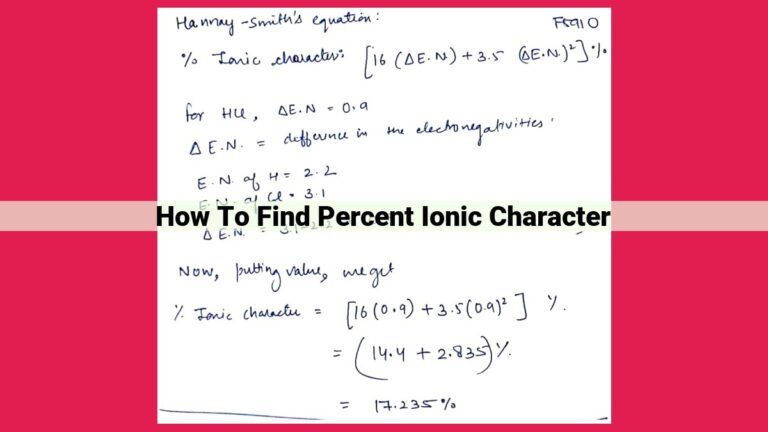

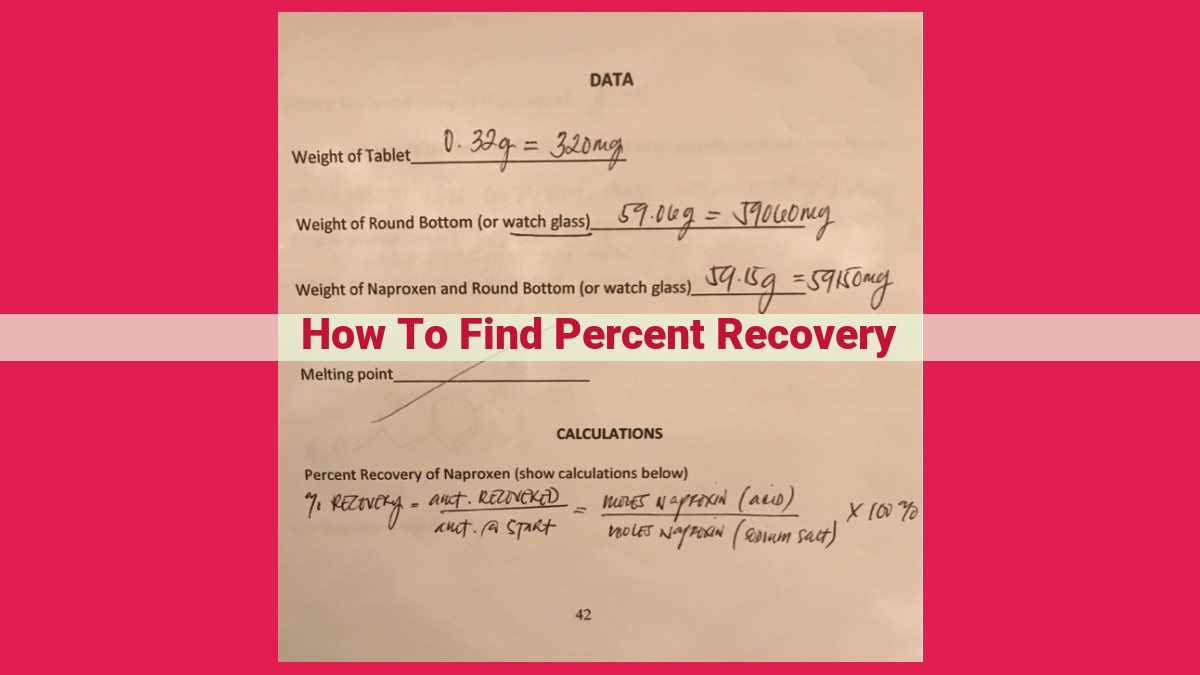

To calculate percent recovery, we use the following formula:

Percent Recovery = (Actual Yield / Theoretical Yield) x 100%

Where:

- Actual Yield: The experimental amount of product obtained from our reaction.

- Theoretical Yield: The maximum amount of product that could be produced based on the stoichiometry of the reaction.

Think of it as a percentage score: a higher percent recovery indicates a more successful reaction, while a lower score highlights potential inefficiencies.

So, why is percent recovery important? It’s a valuable tool for:

- Process Optimization: Adjusting reaction conditions to maximize product yield.

- Comparing Experimental Methods: Evaluating different approaches to achieve the best results.

- Assessing Product Quality: Determining if the obtained product meets the desired specifications.

By understanding the concept of percent recovery and its applications, we gain a deeper understanding of chemical reactions and how to harness their full potential. Remember, it’s not just about obtaining the product; it’s about maximizing its efficiency and unlocking its applications to the fullest extent.

Factors Hampering Percent Recovery: A Behind-the-Scenes Look

When aiming for optimal chemical reactions, achieving high percent recovery is crucial. However, several factors can hinder this efficiency, causing actual yields to fall short of theoretical expectations.

Side Reactions: Unforeseen Chemical Guests

Chemical reactions are not always well-behaved. Side reactions, like unruly guests at a party, can sneak in and steal reactants or products from the main reaction. These uninvited visitors reduce the actual yield by diverting valuable resources.

Reactant Impurities: Hidden Saboteurs

The purity of reactants plays a significant role in percent recovery. Impurities, like tiny grains of sand in a precious gem, can contaminate the reaction and disrupt the stoichiometric balance. These hidden saboteurs lower the quality of the final product and diminish the yield.

Measurement Errors: The Importance of Precision

Precision is paramount in chemistry. Even the slightest measurement errors can have cascading effects on percent recovery. Using inaccurate equipment or reading scales incorrectly can lead to discrepancies between the actual and theoretical yields.

To mitigate these factors and enhance percent recovery, chemists employ various strategies. Optimizing reaction conditions, using high-quality reactants, and ensuring accurate measurement techniques are crucial. With these measures in place, chemists can tame the unruly guests, eliminate hidden saboteurs, and minimize measurement errors, leading to maximized percent recovery and efficient chemical reactions.

Improving Percent Recovery: Strategies for Enhanced Reaction Efficiency

In the realm of chemistry, percent recovery holds immense significance as a measure of a reaction’s yield and efficiency. While it is impossible to achieve perfect recovery due to inherent inefficiencies, there are several proven strategies that can significantly improve your results.

Optimizing Reaction Conditions

The first step towards enhancing percent recovery lies in optimizing the reaction conditions. Temperature, pressure, and the presence of catalysts can all have a profound impact on the reaction rate and product formation. By carefully adjusting these parameters, you can create an environment that favors the desired chemical transformation. For example, increasing the temperature can accelerate the reaction, while using a catalyst can lower the activation energy and improve selectivity.

Using High-Quality Reactants

The purity of the reactants you use is another crucial factor affecting percent recovery. Impurities can compete with the desired reaction, leading to the formation of unwanted byproducts. By using high-quality reactants, you minimize the influence of side reactions and increase the likelihood of obtaining the desired product. Furthermore, using reactants in stoichiometric proportions ensures that neither reactant is present in excess, reducing the potential for unwanted reactions.

Ensuring Accurate Measurement Techniques

Finally, accurate measurement techniques are essential for obtaining reliable percent recovery data. Precise measurement of reactant quantities, reaction times, and product yield ensures accurate calculations. Using properly calibrated equipment and adhering to established measurement protocols minimizes measurement errors that can skew your results.

Remember, improving percent recovery is a continuous process of experimentation and optimization. By implementing these strategies, you can enhance the efficiency of your reactions, maximizing product yield and minimizing waste. In turn, this leads to improved process economics, better scientific outcomes, and a more sustainable experimental approach.

Applications of Percent Recovery

Percent recovery is an invaluable tool in various fields, providing insights into the efficiency and reliability of chemical processes. Here are some of its key applications:

Process Optimization

Calculating percent recovery allows chemists to evaluate the efficiency of a chemical process. By comparing the actual yield to the theoretical yield, they can identify areas where the process can be optimized. For instance, if the percent recovery is low, it may indicate losses due to side reactions or impure reactants. This information can help researchers pinpoint the bottlenecks and implement improvements to enhance the process yield.

Comparison of Experimental Methods

Percent recovery serves as a valuable metric for comparing the effectiveness of different experimental methods. By conducting experiments under various conditions, scientists can determine which method produces the highest percent recovery. This comparison aids in selecting the most efficient experimental protocol for a specific reaction, ensuring reliable and reproducible results.

Assessment of Product Quality

Percent recovery plays a crucial role in assessing the quality of the product obtained. A high percent recovery indicates a pure product with minimal impurities, while a low percent recovery may suggest the presence of contaminants or incomplete reactions. This information is essential for evaluating the product’s suitability for further applications or commercial use.

By understanding the applications of percent recovery, chemists and researchers can harness its power to improve processes, optimize experimental methods, and assess product quality. This valuable metric serves as a cornerstone in the quest for efficient and reliable chemical synthesis.