Unlock The Compressibility Of Matter: Understanding Gas Behavior Under Pressure

What State of Matter Can Be Compressed?

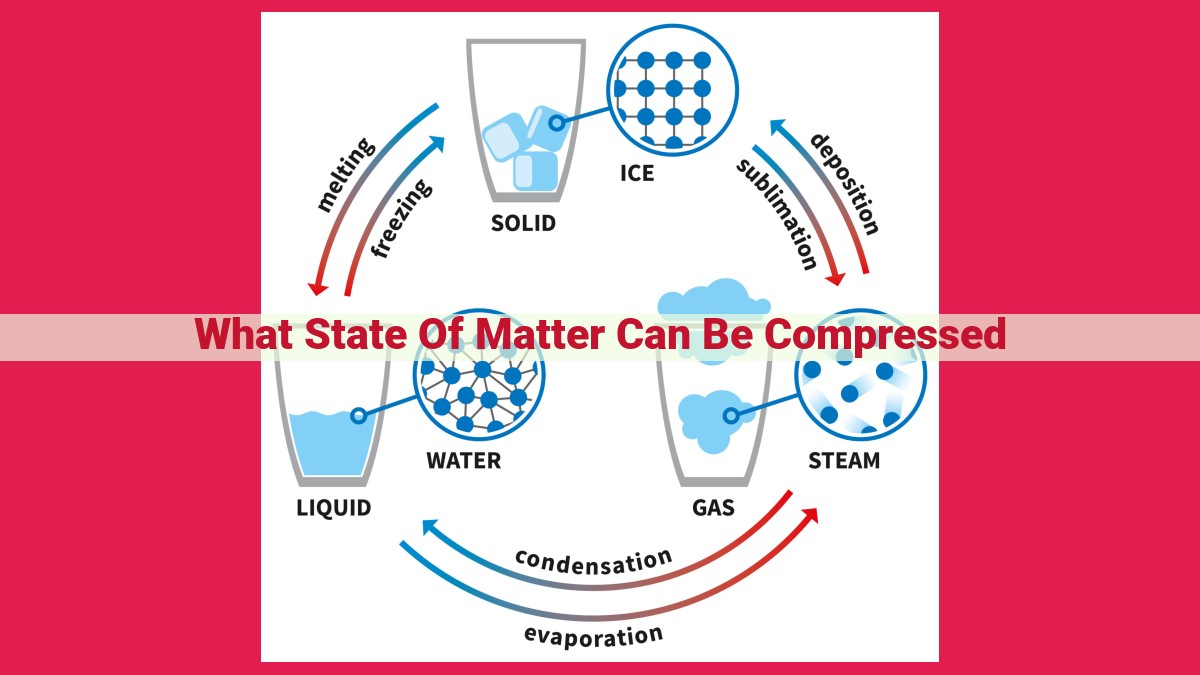

Gases are the only state of matter that can be compressed. When pressure is applied to a gas, its volume decreases while its density increases. This is because gas molecules are loosely packed and have a high kinetic energy, allowing them to move closer together when subjected to external forces. Liquids and solids, on the other hand, are more difficult to compress due to their higher molecular density and stronger intermolecular forces.

Compression, Stress, and Strain: The Mechanics of Squeezing Matter

Compression: The Squeezing Force

Imagine applying pressure to a soft material like a sponge. As you squeeze, you’re compressing it, reducing its volume and potentially changing its shape. This mechanical force, known as compression, is the focus of our exploration.

Stress and Strain: Measuring Compression’s Impact

When you compress a material, it experiences stress, which is the force applied per unit area. The strain is a measure of the material’s deformation, expressed as the ratio of the change in length to the original length.

Elastic Modulus: The Material’s Response

The elastic modulus is a crucial property that describes a material’s response to compression. It measures the material’s stiffness, or resistance to deformation. A high elastic modulus indicates that a material will resist compression more effectively, while a low modulus indicates greater susceptibility to deformation.

Understanding the interplay between compression, stress, strain, and elastic modulus is essential for comprehending how different states of matter behave when subjected to compressive forces. Join us as we delve deeper into the unique characteristics of gases, liquids, and solids under compression.

Gases: Compression and Fluid Dynamics

In the realm of matter, gases hold a unique position. Defined by their dispersed and amorphous nature, gases lack a definite shape or volume. This fluidity makes them highly susceptible to compression or squeezing.

Molecular Density and Kinetic Energy

The compressibility of a gas hinges upon its molecular density and the average kinetic energy of its particles. Molecular density refers to the number of molecules present within a given volume. Higher molecular density means more particles competing for the same space, making the gas more resistant to compression.

Kinetic energy, on the other hand, plays a crucial role in the movement of gas molecules. The higher the kinetic energy, the faster the molecules move, colliding more often and creating more pressure. Thus, gases with higher kinetic energy are more compressible.

Diffusion: The Interplay of Molecules

Diffusion is a fundamental process in gas compression. It describes the movement of gas molecules from areas of high concentration to areas of low concentration. As molecules diffuse, they spread out and fill the available space, reducing the overall pressure. This process is particularly important in the compression of gases, as it facilitates the uniform distribution of molecules throughout the container.

In summary, gases can be compressed due to their fluid nature and the interplay of molecular density, kinetic energy, and diffusion. Understanding these factors is essential for manipulating and controlling gases in various engineering and industrial applications.

Liquids: Viscosity and Surface Tension

Liquids, distinct for their fluid nature, can flow and take the shape of their container. This fluidity exists due to the weak intermolecular forces that hold liquid molecules together. When subjected to compression, liquids exhibit unique responses determined by their viscosity and surface tension.

Viscosity: Resistance to Deformation

Viscosity refers to a liquid’s resistance to deformation or flow. Higher viscosity indicates that the liquid molecules move slowly past each other, resulting in greater resistance to compression. Think of it like trying to squeeze thick honey compared to water. Honey’s higher viscosity makes it more difficult to compress.

Surface Tension: Liquid’s “Skin”

Liquid molecules experience stronger cohesive forces with their immediate neighbors than with air molecules. This creates a “skin” on the liquid’s surface, known as surface tension. This “skin” generates an inward force that resists external compression. Imagine a rubber sheet laid flat on a table; the stretching force applied to its edges is analogous to the surface tension of a liquid.

In conclusion, the compressibility of liquids hinges on their viscosity and surface tension. Viscous liquids resist compression more effectively due to their sluggish molecular motion, while surface tension provides an inward force that further impedes compression. Understanding these properties is crucial for various applications, ranging from fluid dynamics to material engineering.

Solids: Crystal Structure and Material Properties

In the realm of matter, we find solids standing firm, their particles tightly packed together in crystalline structures. This crystal structure dictates the unique properties of each solid, including its response to compression.

Crystal structures are defined by the orderly arrangement of atoms or molecules. This ordered pattern results in strong interatomic bonds, giving solids their characteristic hardness and stiffness. The strength of these bonds determines the compressibility of a solid.

Hardness refers to a material’s resistance to indentation or scratching. Harder materials, like diamond, have tightly packed crystal structures with strong interatomic bonds, making them less compressible. Conversely, softer materials, like lead, have weaker bonds and are more compressible.

Stiffness, on the other hand, describes a material’s resistance to bending or deformation. Stiff solids have a high Young’s modulus, indicating that they require a significant amount of force to compress them. A material’s elasticity also plays a role, as elastic materials can recover their original shape after being compressed.

The crystal structure of a solid not only affects its compressibility but also its other mechanical properties. For example, metals typically have face-centered cubic (FCC) or body-centered cubic (BCC) structures, which give them good strength and ductility. Ceramics, on the other hand, have covalent bonds and ionic bonds, resulting in high hardness and brittle behavior.

Understanding the relationship between crystal structure and material properties is crucial for engineers and material scientists who design and develop materials for specific applications. By manipulating crystal structures, they can tailor the compressibility, hardness, and stiffness of materials to meet the demands of different engineering challenges.