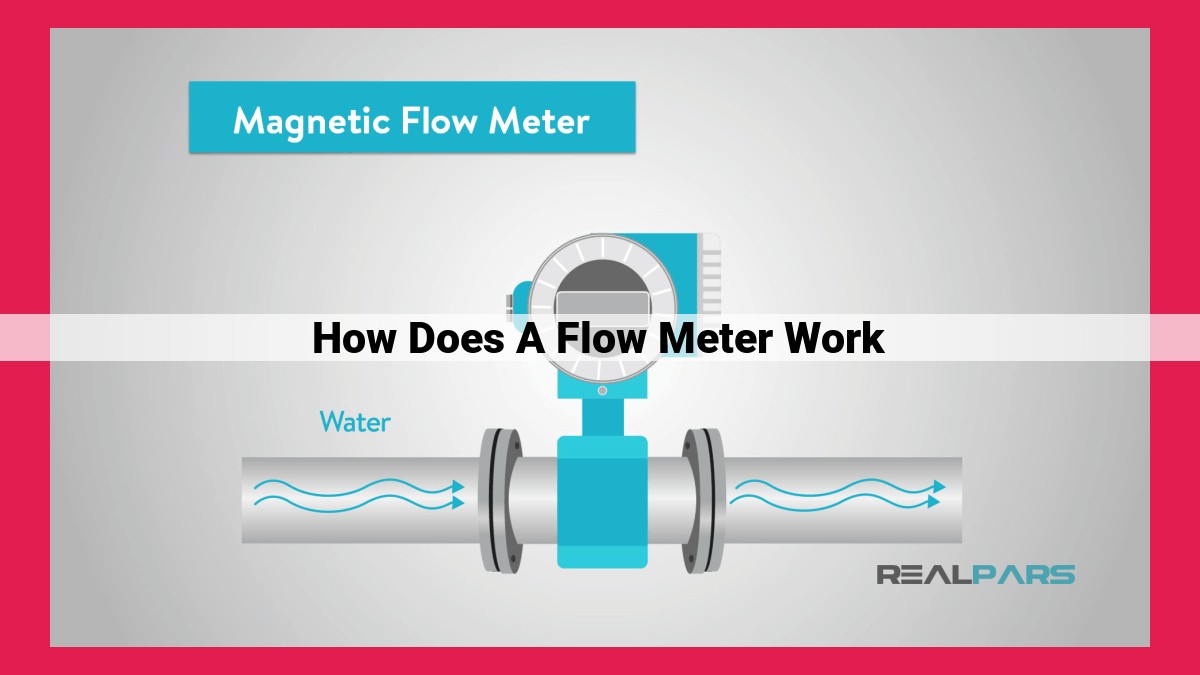

Flow Meters: Precision Devices For Measuring Fluid Flow

Flow meters measure fluid flow rate, a key parameter in various industries. They operate by detecting the velocity of the fluid and converting it into a flow signal. Velocity is inversely proportional to cross-sectional area, and flow meters exploit this relationship by measuring the differential pressure created as the fluid passes through a known cross-sectional area. The differential pressure is then converted into a flow signal, which can be calibrated to accurately represent the flow rate.

Understanding Flow Rate: A Fluid’s Journey

In the world of fluids, understanding how much and how quickly they move is crucial for various applications, from engineering to medicine. Flow rate is the key measurement that quantifies this movement, representing the volume or mass of fluid passing through a channel over a given time.

Imagine a river gracefully flowing down a hillside. Its flow rate is the amount of water that rushes past a certain point in a second. This measurement helps hydrologists predict flooding risks and design efficient irrigation systems. In a similar vein, the flow rate of blood in our arteries is vital for ensuring proper oxygen delivery to our organs.

Measuring flow rate allows us to control and optimize fluid movement in countless industrial and domestic settings. From ensuring a steady supply of gas to furnaces to monitoring the flow of liquids in manufacturing processes, accurate flow rate measurements are essential.

Exploring Velocity:

- Define velocity as the vector quantity denoting fluid speed and direction.

- Relate velocity to flow rate and cross-sectional area, highlighting their inverse relationship.

Understanding Velocity: The Speed and Direction of Fluid Flow

In the realm of fluid dynamics, where fluids reign supreme, velocity is a crucial concept that defines the speed and direction of their movement. Velocity is a vector quantity, meaning it has both a magnitude (speed) and a direction.

Relating velocity to flow rate and cross-sectional area uncovers an intriguing inverse relationship. Imagine a river flowing through a channel. If the flow rate increases, the velocity of the water decreases. This is because the same volume of water is being distributed over a larger area, resulting in a slower flow. Conversely, a smaller cross-sectional area leads to a higher velocity as the water is forced through a narrower passage.

This inverse relationship between velocity and flow rate is a fundamental principle in fluid dynamics. It’s a concept that engineers and scientists use to design and optimize fluid systems in various industrial and scientific applications.

The Role of Cross-sectional Area: A Tale of Flow and Velocity

Imagine a river flowing through a canyon. The cross-sectional area of the river is the area of the channel perpendicular to the flow direction. It’s like the “width” of the river. Now, let’s observe the relationship between this area and the river’s flow rate (the volume of water passing through it per unit time) and velocity (the speed at which the water flows).

As you widen the river (increase its cross-sectional area), you’ll notice something interesting. The flow rate increases because there’s more room for water to pass through. It’s like opening a wider gate, allowing more water to flow out.

But here’s the catch: as the flow rate increases, the velocity of the water decreases. Why? Because the same amount of water is now spread over a larger area. It’s like a crowd of people trying to get through a narrow door. When the door is widened, they can move through it more quickly. But if the crowd is larger, the speed at which they can move through still decreases.

In other words, a larger cross-sectional area allows for a higher flow rate but results in a lower velocity. This relationship is crucial for understanding fluid flow in pipes, channels, and other engineering systems. By manipulating the cross-sectional area, engineers can control the flow and velocity of fluids, optimizing processes and ensuring efficient operation.

The Importance of Calibration for Accurate Flow Measurement

In the world of fluid dynamics, understanding the flow rate, velocity, and other parameters of fluids is crucial for efficient operations. One aspect that plays a vital role in delivering accurate and precise flow measurements is calibration.

What is Calibration?

Calibration is the meticulous process of adjusting flow meters to ensure that their readings align with a known reference standard. It’s like a checkup for your flow meter, ensuring that it’s operating optimally.

Why is Calibration Important?

Accurate readings: Faulty measurements can lead to inaccurate data, affecting decision-making and potentially increasing costs. Calibration minimizes these errors, guaranteeing reliable results.

Compliance and reliability: Many industries have strict regulations regarding flow measurement accuracy. Calibration ensures that your flow meters comply with these standards, enhancing your credibility and reliability.

Improved maintenance: A well-calibrated flow meter will operate within its optimal range, reducing the risk of breakdowns and prolonging its lifespan.

Calibration Methods

Calibration involves comparing the readings of your flow meter to a reference source. There are several methods used for this process:

-

Gravimetric calibration: Measures the weight of the fluid collected over a specific time, providing a reliable volumetric flow rate reference.

-

Volumetric calibration: Utilizes a known volume of fluid to determine the flow rate, ensuring accurate measurements even with varying fluid properties.

-

Differential pressure calibration: Converts the pressure difference across a known restriction into a flow rate signal, suitable for applications with minimal flow rate variation.

Comparison to Reference Sources

The accuracy of calibration depends heavily on the reference source. Reputable calibration laboratories use certified and traceable reference instruments to ensure the highest level of precision.

Regular calibration is essential to maintain the accuracy and reliability of your flow meters. By employing proper calibration techniques, you can trust that your flow measurements are precise, ensuring efficient operations and optimal performance.

Measuring Differential Pressure:

- Explain the concept of differential pressure as the pressure difference between two points in a flow system.

- Discuss its application in measuring flow rate by converting pressure difference into a flow signal.

Measuring Differential Pressure: A Key to Flow Rate Monitoring

In the intricate world of fluid flow, understanding the concept of differential pressure is paramount. Differential pressure, simply put, is the difference in pressure between two points within a flow system. Its measurement holds great significance in the precise monitoring of flow rates.

Imagine a fluid flowing through a pipe. As it travels, the fluid encounters varying levels of resistance, primarily due to factors like friction and changes in pipe diameter. These variations give rise to pressure differences along the pipe’s length.

Differential pressure meters harness this phenomenon to measure flow rate. By sensing the pressure difference between two specific points in the flow system, these meters can provide a reliable indication of the volume or mass of fluid passing through.

The relationship between differential pressure and flow rate is inversely proportional. This means that a higher differential pressure corresponds to a higher flow rate. This inverse proportionality stems from the principle of conservation of energy, which dictates that the total energy of a fluid flowing through a system remains constant.

Therefore, in scenarios where the cross-sectional area and fluid density remain constant, differential pressure can be directly linked to flow rate. This relationship makes differential pressure measurements a widely employed technique for monitoring flow rates in various industrial and scientific applications.

Mass Flow Rate: Beyond the Boundaries of Volume

In the realm of fluid dynamics, we often encounter the concept of flow rate, a measure of the volume or mass of fluid traversing a channel over time. However, there exists a more nuanced aspect known as mass flow rate, which delves into the mass of the fluid flowing per unit time.

Mass flow rate transcends the limitations of volume-based measurements. It offers a deeper understanding of fluid behavior, as it incorporates the density of the fluid. Density represents the mass of the fluid per unit volume, thereby providing a more comprehensive characterization of the fluid’s substance.

Understanding mass flow rate is crucial in various industrial and scientific applications. It plays a pivotal role in the design and operation of pipelines, pumps, and flow meters. By considering both the mass and volume of the fluid, engineers can optimize system performance and ensure accurate measurements.

The relationship between mass flow rate, flow rate, velocity, and cross-sectional area can be expressed as:

Mass flow rate = Flow rate * Density * Cross-sectional area

This equation highlights the interconnectedness of these parameters. For instance, a higher density fluid, such as oil, will result in a higher mass flow rate compared to a lower density fluid, like air, flowing at the same flow rate and through the same cross-sectional area.

Moreover, the influence of viscosity on mass flow rate cannot be overlooked. Viscosity measures a fluid’s resistance to flow. A fluid with high viscosity, like honey, will exhibit a lower mass flow rate compared to a low-viscosity fluid, such as water, under the same conditions. Viscosity affects the velocity profile of the fluid within the channel, influencing the overall mass flow rate.

In practical applications, mass flow meters are employed to measure the mass flow rate of fluids. These devices utilize various principles, such as the Coriolis effect, thermal dispersion, or ultrasonic waves, to accurately determine the mass of the fluid flowing through them.

By understanding and applying the concept of mass flow rate, engineers and scientists can delve deeper into the intricacies of fluid dynamics. It empowers them to design and operate systems more efficiently, optimize fluid handling processes, and gain a comprehensive insight into the behavior of fluids in diverse applications.

Understanding Viscosity: The Hidden Force that Shapes Fluid Behavior

In the captivating realm of fluid dynamics, there exists an enigmatic force known as viscosity, a property that governs a fluid’s resistance to flow. This seemingly abstract concept profoundly influences the behavior of fluids, playing a crucial role in countless applications.

Imagine pouring honey from a jar into a glass. The honey’s sluggish movement is a testament to its high viscosity. The force between the honey’s molecules resists their separation, impeding their flow. Conversely, water, with its lower viscosity, glides effortlessly through a pipe.

Viscosity profoundly impacts flow rate, velocity, and pressure. A highly viscous fluid will exhibit a slower flow rate and lower velocity than a less viscous fluid, all else being equal. This is because the viscous forces hinder the fluid’s movement.

Moreover, viscosity is not just a passive observer; it actively influences pressure within a flow system. As a fluid flows through a pipe, its viscosity creates friction against the pipe walls, generating a pressure drop. This pressure drop is directly proportional to the fluid’s viscosity and the flow rate.

Understanding viscosity is paramount for a variety of applications. In the field of medicine, for instance, the viscosity of blood plays a crucial role in regulating blood flow and maintaining optimal health. In manufacturing, controlling the viscosity of fluids is essential for efficient processing and product quality.

By delving into the enigmatic world of fluid dynamics and embracing the fascinating concept of viscosity, we unlock a deeper understanding of the forces that govern our physical world. This knowledge empowers us to optimize fluid systems, design innovative technologies, and unravel the complexities of nature itself.

Effect of Fluid Density on Flow Rate

Fluids possess a property known as density, which signifies their mass per unit volume. The density of a fluid plays a crucial role in determining its behavior within a flow system.

Impact on Mass Flow Rate

Mass flow rate measures the mass of fluid passing through a point per unit time. It is directly proportional to fluid density. Denser fluids have a higher mass per unit volume, resulting in a greater mass flow rate for the same volume flow rate.

Influence on Volumetric Flow Rate

Volumetric flow rate represents the volume of fluid flowing per unit time. Its relationship with fluid density is inverse. Denser fluids have a smaller volume for the same mass, leading to a lower volumetric flow rate compared to less dense fluids.

Understanding the Interplay

The relationship between fluid density, mass flow rate, and volumetric flow rate is evident in the following equation:

Mass Flow Rate = Fluid Density * Volumetric Flow Rate

This equation highlights that a change in fluid density directly affects both mass flow rate and volumetric flow rate. For example, if the density of a fluid increases, the mass flow rate will increase while the volumetric flow rate will decrease.

In summary, fluid density is a significant factor that influences both mass flow rate and volumetric flow rate. Understanding this relationship is essential for designing and operating flow systems effectively.

Volumetric Flow Rate: Delving into Fluid Measurement

In the realm of fluid dynamics, quantifying the flow of fluids through channels is crucial. Volumetric flow rate, a fundamental concept in this field, measures the volume of fluid passing through a given cross-sectional area per unit time. This metric unveils essential insights into the behavior of fluids in pipelines, pumps, and other fluid systems.

Unveiling the Interdependence of Fluid Parameters

Volumetric flow rate is intricately intertwined with three key fluid parameters: flow rate, velocity, and cross-sectional area. Flow rate represents the total volume of fluid flowing in a particular timeframe, while velocity denotes the speed at which the fluid travels. The cross-sectional area defines the size of the channel through which the fluid passes.

The relationship between these parameters is governed by the principle of conservation of mass. As flow rate remains constant, velocity and cross-sectional area exhibit an inverse relationship. A larger cross-sectional area leads to a slower velocity and vice versa. This interdependence is crucial for optimizing fluid flow systems, ensuring efficient and controlled fluid transfer.

Applications of Volumetric Flow Rate

Understanding volumetric flow rate holds immense practical significance in various industries, including chemical processing, water treatment, and HVAC systems. It enables precise measurement and control of fluid flow, ensuring optimal performance and safety in these applications.

Precise measurement of volumetric flow rate is essential for:

- Monitoring fluid consumption and optimizing resource allocation

- Ensuring product quality and consistency in manufacturing processes

- Maintaining efficient cooling and heating systems for optimal thermal performance

Enhancing Measurement Accuracy: Calibration and Instrumentation

To ensure accurate and reliable volumetric flow rate measurements, calibration is paramount. This process involves comparing the readings of a flow meter with a known reference source, adjusting the meter’s parameters to match the reference values. Proper calibration ensures the flow meter’s accuracy and precision, enabling accurate measurements over time.

Various instrumentation techniques can be employed to measure volumetric flow rate, including:

- Turbine flow meters: Utilize a rotating turbine to measure flow rate based on angular velocity

- Ultrasonic flow meters: Employ acoustic waves to measure fluid velocity and calculate flow rate

- Differential pressure flow meters: Measure the pressure difference across a constriction or orifice to infer flow rate

Volumetric flow rate is a fundamental concept in fluid dynamics, providing crucial insights into fluid behavior and system performance. By understanding the interdependence of flow parameters and the importance of calibration, engineers and technicians can optimize fluid flow systems and ensure accurate measurements. Embracing these principles empowers professionals to enhance fluid management, maximizing efficiency, safety, and overall system performance.