Sure, Here’s An Seo-Optimized Title For The Given Explanation:fall Arrest Systems: Workplace Safety And Injury Preventionhere Are Some Tips For Optimizing Your Title For Seo:use Relevant Keywords. In This Case, “Fall Arrest Systems” Is The Most Important Keyword.keep It Concise. Google Typically Displays Only The First 50-60 Characters Of A Title In Search Results.make It Descriptive. Your Title Should Accurately Reflect The Content Of Your Page.use Numbers And Special Characters. Numbers And Special Characters Can Help Your Title Stand Out In Search Results.incorporate Your Brand Name. If Your Brand Is Well-Known, Including Your Brand Name In The Title Can Help People Find Your Page.

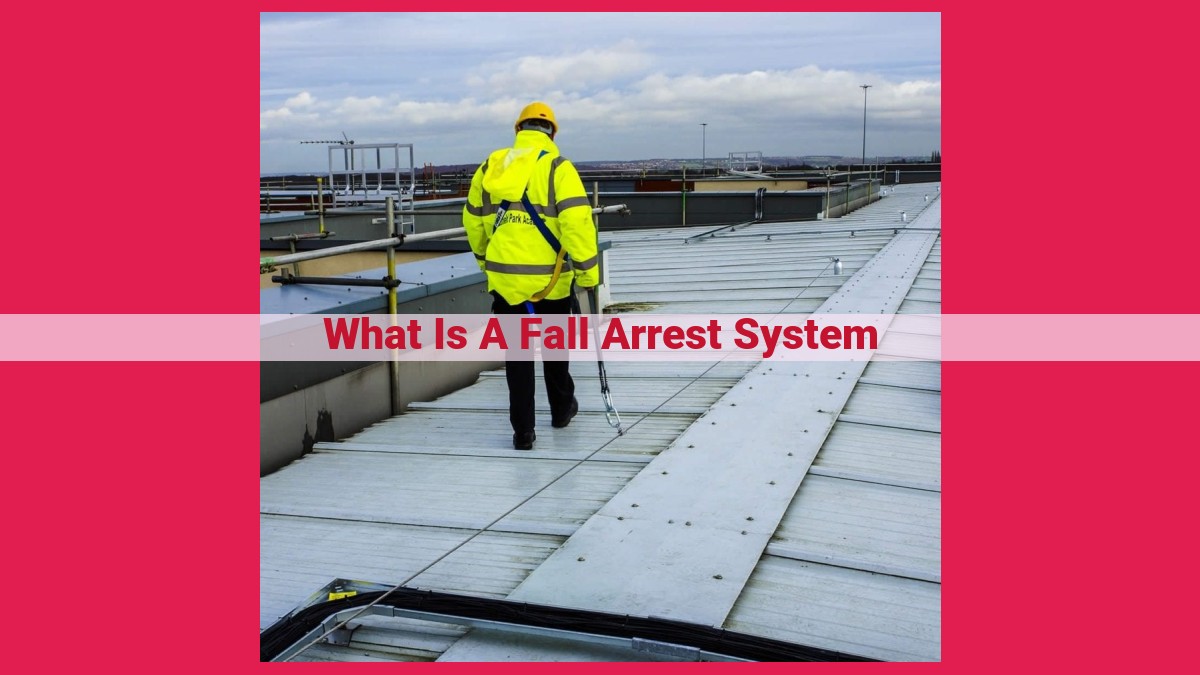

A fall arrest system is a crucial safety solution for preventing or mitigating falls in the workplace. It comprises components like anchorage points, connecting devices, and body harnesses, working together to restrain or arrest a fall and minimize injuries. These systems are essential for safeguarding workers in high-risk environments by reducing fall hazards and adhering to industry regulations and standards. Proper deployment and maintenance of fall arrest systems, along with comprehensive training and emergency protocols, ensure effective protection for individuals working at heights.

Define fall arrest systems and their purpose

Understanding Fall Arrest Systems: A Lifeline for Worker Safety

In the realm of workplace safety, nothing is more paramount than preventing falls. Fall arrest systems stand as indispensable lifelines, safeguarding workers from the catastrophic consequences of a plummet. These intricate systems are engineered to provide a last line of defense, catching workers in the event of a fall and mitigating the risk of injury or death.

The Pivotal Role of Fall Protection

The statistics paint a grim picture: falls remain a leading cause of workplace fatalities and serious injuries. By implementing comprehensive fall protection measures, employers and workers alike can dramatically reduce the likelihood of these accidents. Fall arrest systems play a crucial role in this protective arsenal, complementing other strategies such as fall prevention and mitigation.

Components of a Fall Arrest System

A fall arrest system is a multi-faceted ensemble, encompassing several key components:

-

Anchorage Point: The anchor serves as the foundation, providing a secure connection point for the entire system. It can be either a fixed or temporary structure, meticulously designed to withstand the immense forces generated by a fall.

-

Connecting Device: The connecting device links the worker to the anchorage point. This includes lanyards, lifelines, and shock absorbers, each with unique functions to ensure a smooth and controlled descent in the event of a fall.

-

Body Harness: The body harness is the critical component that cradles the worker in the event of a fall. It distributes the impact forces across the body, minimizing the risk of serious injuries. Harnesses come in various types, from full-body harnesses to waist belts, each tailored to specific work conditions.

Fall Arrest Systems: Essential for Safe Work at Heights

When performing tasks at elevated heights, it’s crucial to implement fall arrest systems to mitigate potential hazards and ensure worker safety. Falls from heights remain a leading cause of workplace injuries and fatalities, making fall protection paramount.

Preventing Catastrophes and Safeguarding Lives

Fall arrest systems act as a last line of defense, preventing workers from plummeting to the ground in the event of a fall. They work by distributing the force of a fall over a wide area, reducing the risk of serious injuries or death. Implementing these systems not only protects individual workers but also reduces costs associated with workplace accidents and downtime.

Beyond Compliance: A Moral Imperative

Protecting employees from harm is not just a legal obligation but a moral imperative. Employers have a responsibility to provide a safe work environment, and fall arrest systems play a vital role in fulfilling this duty. By investing in robust fall protection measures, businesses demonstrate their commitment to the well-being of their workforce and foster a culture of safety.

The Foundation of a Safe Worksite

Fall arrest systems serve as the cornerstone of a comprehensive fall protection program. They provide confidence to workers performing tasks at heights, reducing anxiety and allowing them to focus on their tasks. By eliminating the fear of falling, these systems enhance productivity and boost morale.

Embracing a Culture of Safety

Implementing fall arrest systems goes beyond equipment and procedures. It fosters a culture of safety where workers are aware of the risks, trained to use fall protection gear, and empowered to speak up about potential hazards. This collective responsibility ensures that everyone on site contributes to a safe and healthy workplace.

Anchorage Points: The Foundation of Fall Protection

In the realm of fall protection, anchorage points serve as the cornerstone, providing a secure connection between workers and fall arrest systems. These anchors are essential in preventing falls and mitigating their severity.

Types of Anchorage Points

Anchorage points can be either fixed or temporary. Fixed anchors are permanently installed structures that provide unwavering support. These could include overhead beams, steel columns, or concrete walls. On the other hand, temporary anchors are typically portable devices that can be set up quickly and easily on various work surfaces. They include tripods, roof anchors, and portable base plates.

Strength and Load Capacity Requirements

Strength and load capacity are paramount considerations when choosing an anchorage point. The anchor must be capable of withstanding the full force of a fall, which can be substantial depending on the weight of the worker, equipment, and distance of the fall. Regulations specify that anchorage points must have a load capacity of at least 5,000 pounds, ensuring they can safely support a worker in the event of a fall.

Proper Selection and Use

Choosing the right anchorage point is crucial for effective fall protection. Factors such as the weight of the worker, work environment, and potential fall distance should be carefully assessed. Improper use or selection of anchorage points can significantly compromise worker safety.

Inspection and Maintenance

Regular inspection and maintenance of anchorage points are indispensable for their continued effectiveness. Fixed anchors should be inspected annually by a qualified engineer, while temporary anchors must be inspected before each use. It’s imperative to look for signs of damage, corrosion, or wear that could affect their strength and load capacity.

By understanding the importance, types, and proper use of anchorage points, individuals can enhance the effectiveness of their fall arrest systems and safeguard their well-being in hazardous work environments.

Understanding Fall Arrest Systems

When it comes to protecting workers from the dangers of falling, understanding fall arrest systems is paramount. These systems serve as a safety net, preventing individuals from plummeting to the ground and potential injury. In this article, we’ll delve into the significance of fall protection, the components involved in a fall arrest system, and the regulations and training required to ensure worker safety.

Components of a Fall Arrest System

At the heart of a fall arrest system lies the anchorage point. This is the anchor to which the system is attached, providing a secure connection to the work area. Fixed anchorage points are permanent fixtures, while temporary anchorage points are designed to be set up and removed as needed. Both types must meet strict strength and load capacity requirements to withstand the forces of a potential fall.

Deploying a Fall Arrest System

Selecting the appropriate fall arrest system for a specific worksite is crucial. Factors to consider include the height of the workspace, potential fall hazards, and specific job tasks. Once selected, proper installation and maintenance are essential. Regular inspections and testing ensure the system remains in optimal working condition. Additionally, rescue plans and emergency protocols should be established to address potential fall incidents effectively.

Related Fall Protection Concepts

Fall arrest systems are part of a comprehensive approach to fall protection. Fall prevention techniques aim to eliminate fall hazards, such as guardrails and toe boards. Fall mitigation measures reduce the severity of a fall, including safety nets and energy-absorbing devices. Personal protective equipment (PPE), such as hard hats and safety glasses, complement fall arrest systems to provide additional protection to workers.

Importance of Fall Arrest Systems

The benefits of fall arrest systems cannot be overstated. They prevent catastrophic falls, ensuring the safety and well-being of individuals working at heights. Compliance with industry standards and proper training are essential to maximize the effectiveness of these systems. By embracing fall arrest systems, employers demonstrate their commitment to protecting their workforce and creating a safe and hazard-free work environment.

Understanding Fall Arrest Systems:

In the realm of safety, fall arrest systems stand as indispensable lifelines, preventing potential tragedies at heights. Like a vigilant shield, they intercept falls, absorbing the impact and protecting workers from the deadly consequences of gravity’s pull.

Emphasis on Strength and Load Capacity Requirements:

The anchorage point serves as the anchor for the entire system, demanding unwavering strength to withstand the unforgiving forces of a fall. Its load capacity, meticulously calculated, ensures it can endure the weight of a suspended worker and the additional forces generated by the fall.

Selecting an anchorage point is not a casual endeavor. Rigorous testing and certification are mandatory to guarantee its reliability. Each point must be capable of bearing the maximum anticipated load, which is typically several times the weight of a worker and tools.

By adhering to these stringent requirements, we ensure that the anchorage point remains the steadfast foundation upon which the entire fall arrest system relies. It becomes the rock that safeguards workers, giving them the confidence to navigate heights with peace of mind.

Connecting Devices: The Lifeline to Safety

When it comes to fall protection, connecting devices play a crucial role in anchoring you to a safe point. These components are the lifelines that keep you from falling or, in the event of a fall, limit the impact.

The most common types of connecting devices are:

- Lanyards: Short, flexible lines that attach directly to your body harness and provide a limited range of movement. They come in various lengths and materials, including webbed nylon and steel cable.

- Lifelines: Similar to lanyards, but longer and more durable, typically made of steel or aluminum. Lifelines are installed horizontally or vertically to restrict movement and provide a continuous path for movement.

- Shock Absorbers: Designed to absorb the energy generated during a fall, reducing the force transmitted to your body. These devices usually consist of a coil of webbing or a spring-loaded mechanism.

The type of connecting device you need depends on your specific work environment. Lanyards are suitable for shortfalls from low heights, while lifelines offer more freedom of movement for tasks at greater heights. Shock absorbers, when used in conjunction with lanyards or lifelines, provide additional protection by reducing the risk of severe injuries.

Choosing the Right Connecting Device

Selecting the appropriate connecting device is essential for your safety. Consider the following factors:

- Height of the work area: The higher the potential fall distance, the stronger and more durable your connecting device should be.

- Work environment: The presence of sharp edges, chemicals, or extreme temperatures can affect the choice of materials.

- Frequency of use: If you’ll be using the device regularly, opt for one that is comfortable and easy to use.

Inspection and Maintenance

Regular inspection and maintenance are crucial to ensure your connecting device is functioning correctly. Look for any signs of damage, fraying, or corrosion. Follow the manufacturer’s instructions for cleaning and storage to extend the device’s lifespan and reliability.

Connecting devices are an integral part of any fall arrest system. Understanding their types and functions empowers you to select the right equipment for your work environment. By using connecting devices properly and maintaining them meticulously, you can minimize the risk of falls and protect your safety at heights.

Understanding the Components of Fall Arrest Systems

In the realm of safety, fall arrest systems stand as crucial lifelines. They shield workers from the devastating consequences of falls, ensuring their well-being at perilous heights. To unravel the intricacies of these systems, let’s delve into their components.

Lanyards: The Lifeline’s Extension

Lanyards serve as the flexible connectors between the anchor point and the body harness. Crafted from durable materials like nylon or polyester, they provide workers with freedom of movement while ensuring their safety. Lanyards come in various lengths and configurations, allowing for customization based on the work environment.

Lifelines: The Unwavering Backbone

Similar to lanyards, lifelines are crucial connectors. However, unlike lanyards, they are permanently attached to an anchor point. Their function is to provide a continuous fall protection zone. Lifelines are typically made from galvanized steel or synthetic materials for enhanced durability and longevity.

Shock Absorbers: Cushioning the Impact

Shock absorbers play a vital role in fall arrest systems. They function as energy-dissipating devices that reduce the impact force on workers in the event of a fall. Shock absorbers are usually integrated into lanyards or lifelines and utilize elastic materials or specialized devices to absorb the kinetic energy. Their ability to mitigate the impact reduces the risk of severe injuries or fatalities.

Body Harness: The Lifeline in Fall Protection Systems

In the realm of fall protection systems, the body harness plays a pivotal role in keeping individuals safe from workplace falls. These harnesses provide a secure connection between the user and the fall arrest system, mitigating the risk of a devastating fall.

Types of Harnesses:

There are two primary types of body harnesses:

-

Full-Body Harnesses: As the name suggests, these harnesses envelop the wearer’s entire body. They distribute the force of a fall evenly across the torso, thighs, and shoulders, minimizing the risk of injury.

-

Waist Belts: These harnesses are less restrictive and only encompass the wearer’s waist. While they are more comfortable for certain activities, waist belts offer less protection than full-body harnesses.

Fit and Comfort:

Ensuring a proper fit is crucial for a body harness’s effectiveness. A snug but comfortable fit is essential. The harness should be adjusted so that it fits securely without restricting movement or causing discomfort.

Certification Requirements:

All body harnesses must meet specific safety standards set by regulatory bodies such as OSHA and ANSI. These standards ensure that the harness meets minimum strength requirements and other safety features to withstand the forces encountered in a fall.

The body harness is an indispensable part of any fall arrest system, providing a vital connection between the worker and the safety lifeline. By choosing the right harness and ensuring a proper fit, individuals can work with confidence, knowing that they are protected from the dangers of falls. Remember, in the realm of workplace safety, “harness your safety” is paramount.

Body Harnesses: Cornerstone of Fall Arrest Systems

In the realm of fall protection, body harnesses serve as the critical link that safely secures workers during elevated operations. These harnesses form the foundation of full-body fall arrest systems, essential for protecting individuals against the devastating consequences of a fall.

Types of Harnesses

Body harnesses come in two primary types:

-

Full-Body Harnesses:

These harnesses provide comprehensive protection by distributing the impact of a fall across the entire body. They feature multiple attachment points for lanyards and lifelines, ensuring a secure fit and minimizing the risk of suspension trauma.

-

Waist Belts:

Waist belts offer limited protection compared to full-body harnesses. They are often used in situations where fall hazards are minimal and workers need greater mobility. Waist belts only have one attachment point and do not provide the same level of support as full-body harnesses.

Selection and Fit

Choosing the right body harness is crucial for proper protection. Factors to consider include:

- Worksite conditions: The specific hazards and potential fall distances

- Worker size and weight: Harnesses must fit snugly to ensure proper distribution of impact

- Type of work: Harnesses with specific features (e.g., additional attachment points, tool loops) may be required for certain tasks

Comfort and Certification

Comfort is essential for workers wearing harnesses for extended periods. Harnesses should be ergonomic, with well-padded straps that minimize discomfort. ANSI-approved harnesses have undergone rigorous testing to meet industry safety standards, ensuring reliability and durability.

Body Harness: A Vital Component of Fall Arrest Systems

In a fall arrest system, the body harness serves as the critical link between the user and the anchorage point. Selecting the right harness ensures not only safety but also comfort and functionality for extended periods of work.

Fit and Comfort

A well-fitting body harness is essential for comfort and proper functionality. It should distribute the force of a fall evenly across the body, minimizing the risk of injury. Look for harnesses with adjustable straps that allow for customization to different body types. Padding at the legs and shoulders can enhance comfort during prolonged use.

Types of Harnesses

Full-body harnesses: These provide the most comprehensive protection during a fall. They wrap around the entire body, distributing the force of the fall over multiple points of contact.

Waist belts: These offer limited protection, supporting only the waist. They are typically suitable for tasks involving minimal risk of falling.

Certification and Standards

Ensuring the quality and safety of your body harness is paramount. Look for models that meet industry standards, such as those set by ANSI or OSHA. These certifications verify that the harness has undergone rigorous testing and meets specific performance requirements.

By choosing a body harness that fits comfortably, is appropriate for the task, and meets industry standards, you invest in the safety and well-being of your workers. A properly fitted harness ensures both protection during a fall and comfort for extended periods of work.

Fall Arrest Systems: A Lifeline to Safety in the Workplace

In the tapestry of workplace safety, fall arrest systems stand out as indispensable lifelines, preventing countless tragedies and safeguarding workers’ well-being. OSHA and ANSI, the guardians of safety standards, have meticulously crafted regulations to ensure the effectiveness and reliability of these systems.

Anchorage Points: The Foundation of Fall Prevention

Anchorage points are the sturdy anchors that provide the backbone for fall arrest systems. They must withstand tremendous loads, ensuring they can hold a worker’s weight in the event of a fall. OSHA requires anchorage points to meet specific strength and load capacity standards, and ANSI provides guidelines for selecting and inspecting these critical components. By adhering to these guidelines, employers create a solid foundation for worker safety.

Connecting Devices: The Bridge to Security

Connecting devices, including lanyards, lifelines, and shock absorbers, are the intermediaries that link workers to anchorage points. Lanyards are short, flexible connectors designed to limit the distance of a fall. Lifelines are longer, semi-rigid cables that provide workers with mobility while remaining connected to an anchorage point. Shock absorbers are vital energy-absorbing devices that mitigate the impact forces of a fall, reducing the risk of serious injuries.

Body Harnesses: The Shield for Workers’ Integrity

Body harnesses are the final link in the fall arrest system, providing unwavering protection to workers. They distribute the force of a fall across multiple points of the body, preventing catastrophic injuries to the spine and internal organs. Full-body harnesses offer the highest level of protection, while waist belts are suitable for work at lower heights. Employers must ensure that harnesses are properly fitted, comfortable, and certified to meet OSHA and ANSI standards.

Training and Certification: Empowering Workers with Knowledge

Training and certification are paramount for the effective use of fall arrest systems. OSHA and ANSI mandate that workers receive comprehensive training on the proper selection, installation, inspection, and use of these systems. Certification programs provide workers with the necessary knowledge and skills to work safely at heights. Employers must invest in training and certification to empower workers with the confidence and competence to protect themselves.

By adhering to OSHA and ANSI standards, employers create a work environment where fall arrest systems are not just an afterthought but an integral part of a comprehensive safety program. These standards provide a framework for ensuring the reliability and effectiveness of fall arrest systems, safeguarding workers from the devastating consequences of falls.

Understanding Fall Arrest Systems: Training and Certification for Personnel

Ensuring Safety at Heights: The Importance of Training and Certification

Falls remain a significant hazard in many workplaces, particularly in construction, maintenance, and other industries where workers operate at elevated heights. Fall arrest systems play a crucial role in mitigating these risks, providing a last line of defense against life-threatening injuries. However, their effectiveness depends heavily on proper training and certification for the personnel using them.

OSHA and ANSI Regulations

In the United States, the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) have established stringent regulations for fall arrest systems. These standards dictate minimum requirements for equipment, training, and usage. Employers are legally obligated to comply with these standards to ensure the safety of their workers.

Comprehensive Training Programs

Comprehensive training programs are essential to ensure that personnel fully understand the proper use, inspection, and maintenance of fall arrest systems. These programs should cover topics ranging from:

- System components and their functions

- Hazard assessment and risk identification

- Safe work practices when working at heights

- Emergency procedures and rescue plans

Certification and Recertification

Qualified instructors should conduct training programs, and participants must pass a written exam and practical demonstration to obtain certification. Certifications typically expire after a certain period, usually one to three years, and require recertification to maintain validity.

Benefits of Certified Personnel

Certified personnel demonstrate a thorough understanding of fall arrest systems and are better equipped to:

- Identify potential fall hazards and implement appropriate risk controls

- Select and inspect equipment properly

- Use fall arrest systems confidently and effectively

- Respond to emergencies swiftly and safely

Employer Responsibilities

Employers have a legal duty to provide adequate training and equipment to their employees who work at heights. They must also ensure that employees are certified and have the necessary skills to work safely. Failure to comply with these regulations can result in citations, fines, and even criminal charges.

By investing in comprehensive training and certification programs, employers can enhance their safety culture, reduce the risk of falls, and protect their workers from preventable injuries. Remember, the well-being of your team is paramount, and proper training is the cornerstone of a robust fall protection program.

Discuss employer responsibilities for adequate training and equipment

Employer Responsibilities for Fall Arrest Systems: Ensuring Worker Safety

Deploying a Fall Arrest System

Responsibilities for Employer

As an employer, you hold a paramount responsibility for ensuring the safety and well-being of your workers. This extends to providing adequate training and equipment, particularly when it comes to fall arrest systems.

Training and Certification

OSHA and ANSI standards mandate that personnel working with fall arrest systems receive comprehensive training and certification. This training should cover topics such as:

- System selection, installation, and maintenance

- Proper use and inspection of fall arrest equipment

- Rescue plans and emergency protocols

- Hazard recognition and risk assessment

Training should be conducted by qualified professionals and tailored to the specific hazards encountered at the worksite.

Personal Protective Equipment

Beyond training, employers must also provide their workers with certified personal protective equipment (PPE), including:

- Body harnesses that meet ANSI standards

- Lanyards and lifelines of appropriate length and strength

- Shock absorbers to mitigate fall impact forces

The PPE should be inspected regularly, maintained in good working order, and stored safely when not in use.

Adequate Equipment

Ensuring adequate equipment goes beyond just providing the necessary gear. Employers must also:

- Conduct thorough hazard assessments to identify potential fall risks

- Select fall arrest systems that are suitable for the worksite conditions

- Install and maintain the systems according to manufacturer specifications and industry best practices

By fulfilling these responsibilities, employers create a work environment where employees feel confident in their safety and are less likely to experience fall-related injuries.

Guide to Selecting an Appropriate Fall Arrest System for Worksite Conditions

Selecting the right fall arrest system is crucial for ensuring worker safety and minimizing fall hazards. Here’s a comprehensive guide to help you choose the most suitable system for your worksite:

Assessing Worksite Conditions

The type of work you’re performing, height of the work area, and potential hazards present will determine the system you need. Assess the worksite carefully and consider the following factors:

- Height and Fall Distance: The height of your work area will dictate the length and strength of the lanyard required.

- Work Surface: Verify the type and strength of the anchorage point available.

- Hazards and Obstructions: Identify potential fall hazards and obstacles that may require specific equipment, such as shock absorbers or self-retracting lifelines.

Choosing the Right Components

Once you’ve assessed the worksite conditions, you can select the appropriate components:**

1. Anchorage Point: Opt for fixed anchorage points whenever possible, as they offer reliable and consistent strength.

2. Connecting Device: Choose a lanyard or lifeline with the correct length and load capacity for the worksite. Consider shock absorbers if the potential fall distance is significant.

3. Body Harness: Select a full-body harness that fits snugly and comfortably while distributing impact forces evenly.

Special Considerations

In some cases, you may need additional equipment or specialized systems, such as:

- Horizontal Lifelines: For working on flat surfaces with multiple anchorage points.

- Self-Retracting Lifelines: To provide constant tension and reduce the risk of tripping or entanglement.

- Vehicle-Mounted Systems: For working on tall vehicles or structures.

Importance of Proper Selection and Use

Remember, the effectiveness of a fall arrest system relies on selecting the right equipment and using it correctly. Always train workers on proper installation, inspection, and maintenance procedures. Regular inspections, repairs, and replacements ensure that the system remains in optimal condition and ready to protect workers in the event of a fall.

Essential Fall Arrest System Maintenance for Enhanced Worker Safety

Ensuring the Reliability of Your Fall Protection Gear

Fall arrest systems play a crucial role in safeguarding workers from the hazards of working at heights. However, the effectiveness of these systems relies heavily on proper installation and maintenance procedures. Neglecting regular inspections and preventative maintenance can compromise system integrity, increasing the risk of accidents and injuries.

Key Maintenance Steps for Fall Arrest Systems

To ensure the reliability of fall arrest systems, regular maintenance is paramount. Monthly inspections should focus on visually examining each system component for signs of damage, corrosion, or wear. Annual inspections by a qualified professional should include a thorough examination and documentation of the system’s condition, identify any necessary repairs or replacements, and provide recommendations for enhancing system effectiveness.

Proper Installation and Setup

Proper installation is crucial for the optimal functioning of fall arrest systems. Anchors should be securely attached to structures with sufficient load capacity to withstand the forces of a potential fall. Connecting devices, such as lanyards and lifelines, should meet industry standards and be free from defects or damage. Body harnesses should be adjusted to fit the user comfortably and securely, with all straps and buckles fastened.

Training and Compliance

Regular training for workers and employers is essential for ensuring proper system usage and maintenance. Employees should receive instruction on the types and functions of fall arrest equipment, appropriate deployment methods, inspection procedures, and rescue protocols. Employers are responsible for providing adequate training and equipment, as well as enforcing compliance with safety regulations.

Consequences of Neglecting Maintenance

Failure to maintain and inspect fall arrest systems can have dire consequences. Damaged or improperly installed components may not activate or fail during a fall, increasing the risk of injury or fatality. Lack of training can lead to incorrect use of equipment or failure to recognize potential hazards, further compromising worker safety.

Investing in Safe Practices: A Duty of Care

By adhering to rigorous maintenance and installation procedures, employers can demonstrate their commitment to worker safety and mitigate the risks associated with falls from heights. Investing in fall protection is not only a legal obligation but also an ethical responsibility to provide a safe work environment.

Deploying a Fall Arrest System

Establish Rescue Plans and Emergency Protocols

In the unfortunate event of a fall, it is imperative to have thoroughly planned and practiced rescue protocols in place. These measures can mean the difference between life and death and ensure a prompt and effective response to a fallen worker.

Identify Potential Rescue Scenarios:

- Determine the most likely fall scenarios based on the worksite conditions and equipment used.

- Consider factors such as height of the fall, obstructions, and access to the victim.

Develop a Rescue Plan:

- Assign designated rescuers with proper training and responsibilities.

- Outline specific actions to be taken, including how to access the fallen worker, provide first aid, and initiate evacuation.

- Establish clear communication protocols for reporting incidents and coordinating rescue efforts.

Regular Drills and Training:

- Conduct regular drills to practice the rescue plan and familiarize rescuers with their roles.

- Train personnel on proper rescue techniques, including handling equipment, accessing victims, and implementing emergency procedures.

- Document all drills and training for record-keeping and evaluation.

Emergency Equipment:

- Ensure the availability of essential rescue equipment, including ladders, ropes, stretchers, and first aid kits.

- Store equipment in easily accessible locations and ensure it is properly maintained and inspected.

Collaboration with Emergency Services:

- Establish protocols for coordinating with local emergency services in case of serious accidents or complex rescue operations.

- Provide emergency responders with site-specific information and access to rescue plans.

By establishing comprehensive rescue plans and emergency protocols, employers can create a safer work environment and ensure that fallen workers receive the timely and effective assistance they need.

Fall Prevention: Techniques to Eliminate Fall Hazards

In the realm of workplace safety, nothing is as crucial as preventing falls. Fall prevention involves identifying and mitigating potential fall hazards, thereby eliminating the risk of an accident before it occurs. This proactive approach is essential for creating a secure and healthy work environment.

Engineering Controls:

One of the most effective fall prevention techniques is through engineering controls. This involves modifying the worksite or equipment to eliminate fall hazards. For instance, installing guardrails, toe boards, and covers on floor openings can create physical barriers that prevent workers from falling. Similarly, providing safe access ladders and platforms ensures that workers have secure pathways to reach elevated areas.

Work Practice Modifications:

Another crucial aspect of fall prevention is implementing safe work practices. This includes establishing clear guidelines for working at heights, such as prohibiting work on unstable surfaces or without proper fall protection equipment. Regular safety training and supervision help reinforce these practices and ensure that workers adhere to them.

Eliminating Hazards at Source:

In some cases, it’s possible to eliminate fall hazards completely. This may involve redesigning work processes to reduce the need for working at heights. For example, using scissor lifts or elevated platforms instead of ladders can eliminate the risk of falling from heights. By addressing fall hazards at their source, businesses can create a fundamentally safer workplace.

Fall prevention is a critical component of workplace safety. By implementing engineering controls, modifying work practices, and eliminating hazards at the source, employers can create a work environment where the risk of falling is minimized. This not only protects workers from injury but also promotes productivity and reduces the cost of workplace accidents. By prioritizing fall prevention, businesses can ensure a safe and secure workplace for their employees.

Fall Mitigation: Lessening the Impact of a Fall

In the realm of fall protection, fall mitigation plays a crucial role in reducing the severity of a fall, should it occur. This involves strategically employing measures that minimize the distance travelled and decelerate the fall to prevent serious injuries.

One of the primary means of fall mitigation is the use of energy-absorbing lanyards. These clever devices incorporate a shock absorber that stretches and tears during a fall. This controlled release of energy dampens the impact on the worker, reducing the strain on their body.

Proper system design is also essential for effective fall mitigation. The length of the lanyard is carefully calculated to ensure it does not allow the worker to reach the ground or any other surface that could cause significant injury.

Additionally, self-retracting lifelines provide continuous fall protection. These devices automatically retract the lifeline, keeping the worker close to the anchorage point and minimizing the fall distance.

Proper anchorage points also contribute to fall mitigation. A securely anchored horizontal lifeline allows a worker to travel along a specific path, limiting their potential fall distance.

By employing these fall mitigation techniques, we can significantly reduce the severity of a fall and enhance the safety of workers in elevated work environments.

Personal Protective Equipment (PPE): Partners in Fall Safety

Protecting Workers at Height

Safeguarding workers from falls is paramount, and a comprehensive fall arrest system plays a critical role. While a fall arrest system forms the anchor, a range of Personal Protective Equipment (PPE) complements its effectiveness, ensuring comprehensive protection for workers operating at elevated heights.

PPE, such as hard hats, provides head protection from falling objects or debris. Safety glasses shield eyes from airborne particles, while gloves prevent cuts and abrasions during equipment handling. High-visibility clothing enhances visibility, alerting others to the worker’s presence.

Specialized Footwear

Slip-resistant, safety-toed boots are essential for workers navigating uneven or slippery surfaces. They provide traction and protection against potential foot injuries. Boots with built-in ankle support offer stability and prevent twisting and sprains.

Specialized Gear for Specific Hazards

Depending on the work environment, additional PPE may be necessary. Respirators safeguard against harmful fumes or airborne contaminants, while earplugs reduce noise exposure. Fire-retardant clothing is essential for environments with potential fire hazards.

Importance of PPE Integration

Integrating PPE into a comprehensive fall arrest system creates a multi-layered safety net. Each element works in tandem, enhancing overall protection. A well-maintained and properly used PPE reduces the likelihood of secondary injuries during a fall, such as headtrauma or lacerations.

Compliance and Training

OSHA and ANSI standards mandate the use of appropriate PPE for fall protection. Employers must provide training on the proper use, maintenance, and inspection of PPE. Regular inspections ensure that all equipment is in good condition, and timely repairs or replacements prevent safety breaches.

A fall arrest system combined with the appropriate PPE creates a robust safety alliance, safeguarding workers operating at heights. Compliance with regulations and thorough training are essential for maintaining a safe work environment. By investing in a comprehensive approach to fall protection, employers demonstrate their commitment to the well-being of their workforce.

Understanding Fall Arrest Systems: Protecting Workers from Heights

Falls from heights remain a significant workplace hazard, accounting for numerous injuries and fatalities each year. Fall arrest systems serve as a critical safety measure to mitigate these risks and provide a crucial lifeline for workers operating at elevated levels.

Components of a Fall Arrest System

A comprehensive fall arrest system consists of several essential components, each playing a crucial role in ensuring worker safety:

-

Anchorage Point: A strong and reliable structure that provides a secure attachment point for the connecting device.

-

Connecting Device: A flexible element, such as a lanyard or lifeline, that connects the body harness to the anchorage point and absorbs impact forces in the event of a fall.

-

Body Harness: A wearable device that distributes the impact forces of a fall across the wearer’s body, minimizing injuries.

Regulations and Training for Fall Arrest Systems

OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) establish strict standards for fall arrest systems, ensuring their proper design, installation, and use. To ensure compliance and worker safety, thorough training and certification are mandatory for personnel responsible for deploying and maintaining fall arrest systems.

Importance of Fall Arrest Systems

The significance of fall arrest systems cannot be overstated. These systems play a vital role in:

-

Preventing Injuries and Fatalities: Fall arrest systems provide a crucial safety net, preventing workers from sustaining catastrophic injuries or even death in the event of a fall.

-

Maintaining Productivity: By mitigating fall hazards, fall arrest systems allow workers to operate at heights with confidence, reducing downtime and lost productivity.

-

Creating a Safer Work Environment: When fall arrest systems are implemented and maintained properly, they create a safer and more secure work environment, fostering employee peace of mind and reducing insurance liabilities.

Call to Action

Ensuring the safety of workers operating at heights is paramount. By understanding the components, regulations, and benefits of fall arrest systems, and by investing in comprehensive training, employers can effectively mitigate fall hazards and create a more secure work environment for their valued employees.

Fall Arrest Systems: A Critical Component of Worker Safety

Height-related jobs pose significant risks to workers. Without proper safeguards, a single fall can have devastating consequences. Fall arrest systems serve as a crucial safety net, preventing serious injuries and even fatalities.

Understanding the Importance of Compliance and Training

The effectiveness of fall arrest systems hinges on strict adherence to industry standards and proper training. OSHA and ANSI regulations meticulously outline the requirements for these systems, ensuring they meet rigorous safety criteria.

Compliance with these regulations is not merely a bureaucratic formality; it’s a testament to an organization’s commitment to worker well-being. Employers have a fundamental responsibility to provide adequate training to their employees, empowering them with the knowledge and skills to use fall arrest systems effectively.

Trained personnel understand the selection, installation, and maintenance of these systems. They are also aware of proper rescue protocols and emergency response procedures. This comprehensive training ensures that workers can confidently rely on these safety measures in hazardous situations.

Investing in compliance and training not only safeguards workers but also protects businesses. By preventing accidents, organizations can reduce their liability and insurance costs while fostering a safer and more productive work environment.

Fall arrest systems are an indispensable component of worker safety, providing a vital lifeline in the event of a fall. However, their efficacy is contingent upon strict compliance with regulations and comprehensive training. Employers who prioritize compliance and training demonstrate their commitment to their workforce and create a culture of safety excellence. Remember, the well-being of workers is paramount, and every measure taken to prevent falls is an investment in the future of your business.