Understanding Equivalent Units Of Production: A Comprehensive Guide For Costing And Productivity

Equivalent units of production (EUP) measure work completed, regardless of status. To calculate EUP, consider beginning and ending work-in-process (WIP) units, along with units started during the period. Determine WIP units’ percentage of completion. EUP is calculated as: Completed Units x 100% + (Ending WIP Units x % Completion). EUP is crucial in process and job order costing, tracking production progress, and allocating costs. It helps manufacturers understand their productivity and make informed decisions.

- Define equivalent units of production (EUP) as a measure of work completed regardless of completion status.

Understanding Equivalent Units of Production: The Key to Accurately Tracking Production

In the bustling world of manufacturing, accurately tracking production is crucial for making informed decisions. Equivalent units of production (EUP) serve as an essential tool for this purpose. EUP measures the work completed during a production period, regardless of the actual completion status of each unit. This concept plays a pivotal role in ensuring precise cost allocation and optimizing production processes.

Breaking Down Work in Process (WIP)

WIP refers to units that are partially finished at the end of a production period. To calculate EUP, we need to consider both beginning WIP (units carried over from the previous period) and ending WIP (units still in progress). By understanding the percentage of completion for ending WIP, we can determine the equivalent output of these units.

Calculating Units Started and Percentage of Completion

Units started into production represent those introduced during the period. Percentage of completion estimates the level of completion for ending WIP units based on factors such as materials added, labor performed, or time elapsed. Accurately determining these values is essential for precise EUP calculation.

Calculating Equivalent Units of Production

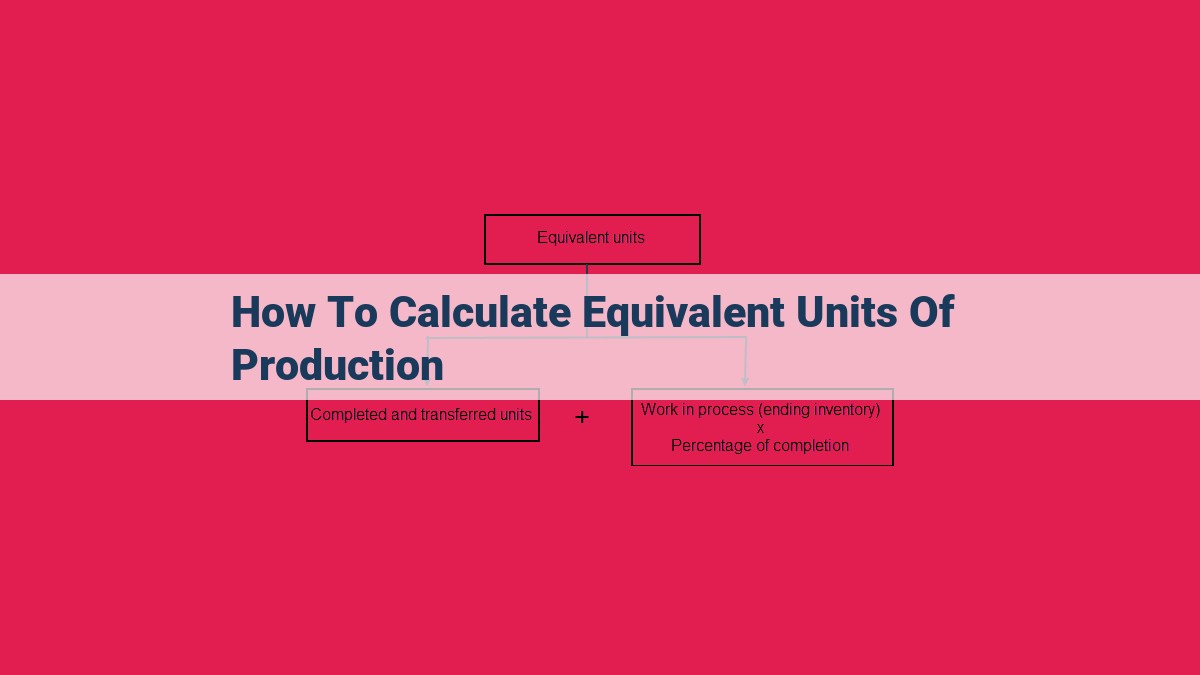

The formula for calculating EUP is as follows:

EUP = Units Completed x 100% + (Units in Ending WIP x % of Completion)

This formula assigns 100% equivalence to fully completed units and adjusts for the partial completion of ending WIP units. By summing the equivalent output of both completed units and ending WIP, we obtain the total EUP for the period.

Applications of EUP

EUP finds extensive application in process costing and job order costing systems. It enables manufacturers to:

- Track production progress and identify bottlenecks

- Allocate costs accurately to units produced

- Make informed decisions on inventory management and production scheduling

- Compare production efficiency across different periods or facilities

EUP is a fundamental concept in production management, providing a standardized measure of work completed. By considering both completed units and ending WIP, EUP ensures precise cost allocation and helps manufacturers optimize their production processes. Understanding the steps for calculating EUP and its applications is crucial for businesses seeking to enhance their manufacturing efficiency and make informed decisions.

Understanding Work in Process (WIP)

What is WIP?

In the manufacturing world, Work in Process (WIP) refers to partially finished goods that are neither completed nor raw materials. These items are in various stages of completion at any given time. WIP is essentially a snapshot of the production process, capturing the value and progress of goods as they move through the manufacturing cycle.

Types of WIP

WIP can be categorized into two types:

- Beginning WIP: Units carried over from the previous production period that are not yet complete.

- Ending WIP: Units that are partially finished at the end of the current production period. These units will be further processed in subsequent periods.

Importance of WIP

WIP is a critical aspect of production accounting. It helps manufacturers track the progress of production, allocate costs accurately, and make informed decisions about resource allocation. By understanding WIP, companies can identify bottlenecks, optimize production schedules, and ultimately increase efficiency.

Calculating Units Started and Percentage of Completion

In the manufacturing realm, it’s crucial to track the progress of work-in-process (WIP) as products journey through different stages of production. Understanding how many units have been started and their level of completion at any given time is essential for accurate cost accounting.

Units Started into Production

Units started into production refer to the number of units introduced into the production process during a specific period. These are units that were not present as WIP at the beginning of the period. Imagine a factory that starts producing 100 units of widgets in a month. These 100 units represent the units started into production for that period.

Percentage of Completion

Percentage of completion is an estimate of how far along units in ending WIP are towards being fully completed. This estimate is expressed as a percentage. For example, if ending WIP units are determined to be 50% complete, it means that they are halfway through the production process.

To determine the percentage of completion for ending WIP units, manufacturers often use various techniques such as physical inspection, review of production records, or time studies. This estimate allows for a more accurate calculation of equivalent units of production, which is discussed in the next section.

Calculating Equivalent Units of Production: A Step-by-Step Guide

In the world of manufacturing, tracking production progress is essential for optimizing costs and making informed decisions. One key measure used in this process is equivalent units of production (EUP). EUP provides a standardized way of quantifying the amount of work completed, regardless of whether the units are fully finished or still in progress.

The Concept of EUP

Imagine a factory that produces widgets. At the beginning of the month, they have 50 unfinished widgets from the previous period (called beginning work in process or WIP). During the month, they start 100 new widgets into production. By the end of the month, they have completed 120 widgets and have 30 widgets left that are partially finished (called ending WIP).

To accurately track progress and allocate costs, we need to consider both the completed units and the ending WIP. This is where EUP comes in.

Calculating EUP

The formula for EUP is:

EUP = Units Completed x 100% + (Units in Ending WIP x % of Completion)

-

Units Completed: This is the number of widgets that were fully finished during the period (120 in our example).

-

Units in Ending WIP: This is the number of widgets that were partially finished at the end of the period (30 in our example).

-

% of Completion: This is an estimate of how much of the ending WIP units are completed. It is usually expressed as a percentage (0-100%). For example, if the ending WIP units are estimated to be 75% complete, the % of completion would be 75%.

Applying the Formula

Using our example, we can calculate EUP as follows:

EUP = 120 x 100% + (30 x 75%)

EUP = 120 + 22.5

EUP = 142.5

This means that the equivalent units of production for the month are 142.5. This is equivalent to completing 142.5 widgets from start to finish.

Importance of EUP

EUP is a valuable tool for manufacturers because it:

- Provides a consistent measure of work completed, regardless of completion status.

- Assists in allocating production costs more accurately.

- Helps track production progress and identify bottlenecks.

- Supports informed decision-making related to production levels and resource allocation.

Applications of Equivalent Units of Production (EUP)

Navigating the intricacies of manufacturing can be like navigating a complex maze, but understanding Equivalent Units of Production (EUP) can serve as a guiding light, shedding clarity on production progress and cost allocation. EUP empowers you to measure work completed, regardless of its completion status, offering a comprehensive snapshot of your manufacturing process.

In the realm of process costing, EUP plays a pivotal role in calculating the cost per unit of production. By considering both completed units and units in ending WIP (Work in Process), EUP provides an accurate representation of the work accomplished during a specific period. This information is essential for determining the unit cost and valuing the inventory at the end of the period.

EUP’s significance extends to job order costing as well. In this context, EUP assists in tracking the production progress of individual job orders. By calculating the EUP for each job, manufacturers can gain insights into the completion status of each order, enabling them to make informed decisions about production scheduling and resource allocation.

Moreover, EUP serves as a valuable tool for allocating overhead costs to production. By determining the proportion of resources consumed by each unit of production, manufacturers can accurately assign these costs to the finished goods and work in process. This precise allocation ensures that each unit bears its fair share of overhead expenses.

Key Insights

- Process Costing: EUP forms the foundation for calculating unit costs and valuing inventory, providing a comprehensive view of production progress.

- Job Order Costing: EUP enables tracking of individual job orders, facilitating informed decisions on scheduling and resource management.

- Overhead Cost Allocation: EUP aids in the accurate allocation of overhead costs to production units, ensuring equitable cost distribution.