Discover Zinc’s Versatility: From Silver Sheen To Dull Finishes And Industrial Applications

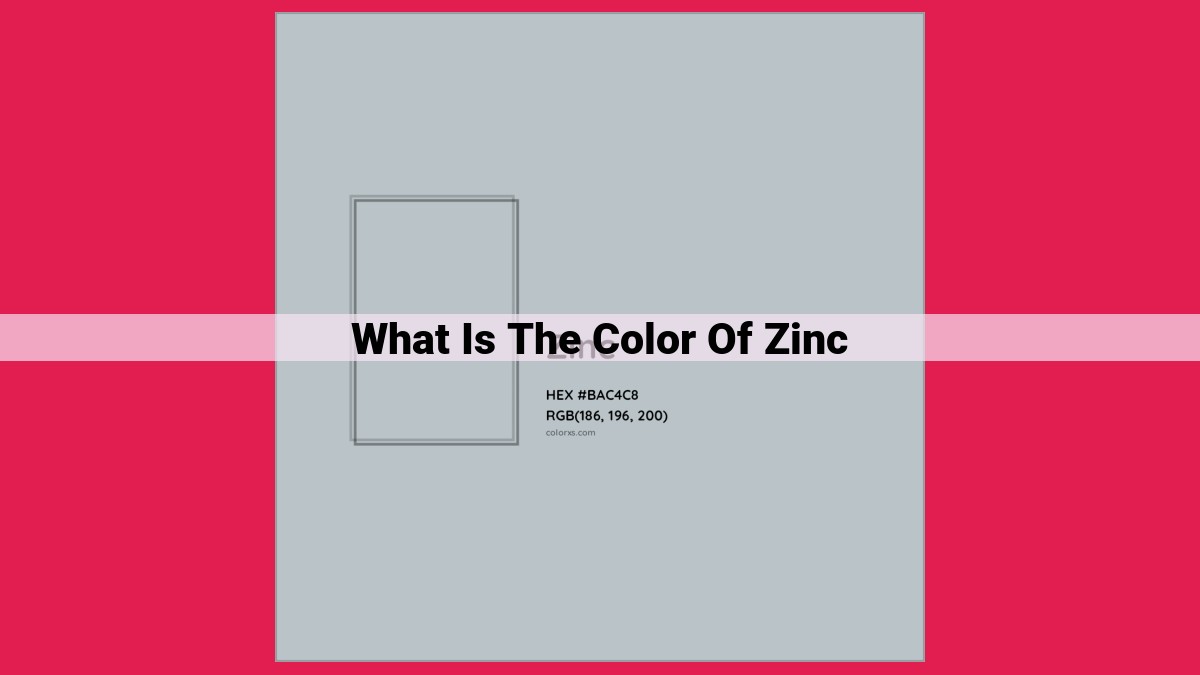

Zinc’s allure lies in its silvery sheen, a metallic luster akin to silver, aluminum, and nickel. This brilliance stems from its reflective properties, enhanced by its crystalline structure. However, time and elements can tarnish zinc, altering its appearance. Dull finishes, distinct from shiny surfaces, unveil another facet of zinc’s color spectrum. Its versatility extends beyond aesthetics, with unique properties that find applications across industries.

Zinc’s Silvery Sheen: A Metallic Marvel

Zinc, a versatile metal renowned for its lustrous sheen, stands out among other silvery metals like silver, nickel, and aluminum. Its silvery brilliance captivatingly reflects light, showcasing a shimmering allure that has captivated humans for centuries.

The reflective properties of zinc are attributed to its unique crystalline structure and the presence of free electrons on its surface. These electrons readily interact with light waves, causing them to bounce off the metal’s surface, resulting in the distinctive silvery luster that characterizes zinc.

Zinc’s Metallic Luster: A Shining Glory

In the realm of metals, zinc stands apart with its captivating silvery luster, a gleaming characteristic that distinguishes it from the mundane. Its brilliance rivals that of chrome, surpassing the subtlety of silver and outperforming the warmth of copper. Zinc’s unique radiance stems from its very structure, a crystalline arrangement that plays a pivotal role in this metallic marvel.

Metallic luster, the hallmark of many metals, arises from the orderly arrangement of atoms within their crystalline lattice. This precise alignment allows for the efficient reflection of light, giving rise to the characteristic sheen. Zinc’s crystalline structure is particularly conducive to this phenomenon, with its tightly packed atoms creating a highly reflective surface. Consequently, zinc gleams effortlessly, mirroring its surroundings with remarkable clarity.

The intensity of zinc’s luster sets it apart from other metals. While chrome possesses a dazzling brilliance, zinc’s luster exhibits a more diffused, silvery glow. Silver, renowned for its purity, pales in comparison to zinc’s vibrant radiance. Copper, with its warm undertones, complements zinc’s cool, silvery appeal. The versatility of zinc’s luster makes it a sought-after material for diverse applications, ranging from decorative accents to industrial components.

Tarnished Beauty: Zinc’s Changing Colors Unraveled

When it comes to metals, their appearance often captivates our gaze. Zinc, a versatile metal known for its silvery sheen, undergoes a remarkable transformation as it interacts with time and its surroundings. This transformation, known as tarnishing, adds a touch of aged elegance to zinc’s surface.

Understanding Tarnishing: A Chemical Process Unveiled

Tarnishing is a natural process that occurs when a metal reacts with the elements in the environment, forming a protective layer. In the case of zinc, this layer is composed of zinc oxide and zinc carbonate. While this layer shields the metal from further corrosion, it also alters its appearance, creating a dull and weathered patina.

A Comparison with Other Metals: Zinc’s Unique Tarnish

Zinc’s tarnishing process differs from that of other common metals. Unlike copper, which develops a vibrant green patina over time, or silver, which tarnishes to a dark and discolored state, zinc’s tarnish is more subtle, resulting in a grayish or brownish hue.

The Chemical Dance: Zinc’s Tarnishing Journey

The chemical reactions involved in zinc’s tarnishing are fascinating. Zinc atoms, eager to interact with their environment, react with oxygen and carbon dioxide in the air, forming zinc oxide and zinc carbonate. These compounds, being less reactive, create a protective barrier on the zinc’s surface, preventing further deterioration.

Tarnishing, often associated with aging, can be seen as a natural and beautiful process that enhances zinc’s character. It is a testament to the metal’s resilience and its ability to adapt to its surroundings. As we observe zinc’s changing colors, we witness a story of time, environment, and the unique qualities of this remarkable metal.

Dull Finishes: Unveiling Zinc’s Other Side

Understanding Dullness

Dullness is a characteristic that refers to the absence of shine or reflectivity. It occurs when light interacts with a surface and is scattered in various directions instead of being reflected back in a specular manner. This scattering is often caused by roughness or irregularities on the surface.

Zinc’s Dull Finish

In comparison to its silvery luster when polished, zinc can also exhibit a dull finish. This occurs when the surface of the metal becomes oxidized or coated with other materials. Unlike the smooth and even surface of polished zinc, a dull finish is characterized by imperfections and discontinuities, such as microscopic pits or corrosion products.

Factors Influencing Zinc’s Dullness

The dullness of zinc can be influenced by several factors, including:

- Exposure to Moisture and Oxygen: Zinc readily reacts with oxygen and moisture in the air, forming a protective layer of zinc oxide on its surface. This oxide layer can dull the metal’s appearance by scattering light more effectively.

- Environmental Conditions: Harsh environments, such as those with high humidity or industrial pollutants, can accelerate the oxidation process, leading to more pronounced dullness.

- Surface Treatment: Mechanical treatments, such as sandblasting or grinding, can create a more textured surface that scatters light more diffusely, resulting in a dull finish.

Comparison to Other Materials

Zinc’s dull finish differs from the dull finishes of other metals in subtle ways:

- Rusty Iron: Dull iron surfaces typically exhibit a reddish-brown color due to the formation of iron oxide (rust), which has a rough and porous texture.

- Copper Patina: Dull copper develops a greenish-blue patina over time due to oxidation and the formation of copper carbonates.

- Oxidized Aluminum: Dull aluminum surfaces often appear gray or black due to the formation of an oxide layer that is non-reflective.

Zinc’s dull finish is a result of its unique surface characteristics and interactions with the environment. Whether silvery and shiny or dull and muted, zinc’s versatile appearance allows it to adapt to various applications, from decorative elements to functional components. Understanding the factors that influence zinc’s dullness can help us appreciate the diverse color canvas this remarkable metal offers.

Zinc’s Unique Features: Unveiling a Versatile Metal

Zinc’s chameleon-like ability to transform its appearance is just one of its many captivating qualities. Its lustrous sheen, silvery gleam, and dull patina offer a diverse palette for a wide range of applications. But beyond its captivating colors, zinc possesses an array of unique properties that make it an invaluable material in various industries.

Exceptional Corrosion Resistance:

Zinc’s exceptional resistance to corrosion, particularly in humid environments, makes it an ideal choice for galvanizing steel and protecting it from rust. Its ability to form a protective zinc oxide layer on its surface not only safeguards steel structures but also extends their lifespan, saving both time and resources.

Excellent Electrical Conductivity:

Zinc’s impressive electrical conductivity places it among the top performers. This property finds practical applications in electrical wiring, batteries, and solar panels, enabling the efficient flow of electricity. Zinc’s contributions to energy storage and transmission have made significant strides in sustainable energy solutions.

** Malleable and Ductile Nature:**

Zinc’s malleability and ductility make it highly workable. It can be easily shaped, extruded, and rolled into a variety of forms, including sheets, coils, and wires. This versatility allows for intricate and customized fabrications, opening up endless possibilities in design and construction.

Biocompatibility and Medical Applications: Zinc’s biocompatibility, combined with its antimicrobial properties, has paved the way for its use in medical devices and implants. Its presence in alloys like brass and stainless steel inhibits bacterial growth, making them suitable for surgical instruments and medical equipment. Zinc’s essential role in human health further underscores its significance in the medical field.

Unleashing Zinc’s Potential:

Beyond its traditional applications, zinc’s unique properties continue to inspire innovation and explore new frontiers. Its corrosion resistance makes it a promising material for marine and offshore structures, while its electrical conductivity holds great potential in the development of advanced electronic devices and renewable energy systems. Zinc’s versatility invites further research and exploration, unlocking its full potential in various industries and shaping the future of technology.