Current Measurement Equipment: Comprehensive Guide For Accurate Readings

To measure current, you can use primary instruments like ammeters or galvanometers. For non-contact measurements, Hall Effect Sensors and Rogowski Coils are employed. For high-precision, Fluxgate Sensors and Zero-Flux Current Transformers provide accurate readings. Convenient options include Clamp-On Ammeters and Digital Multimeters. Consider factors like measurement range, accuracy, and safety when selecting an instrument. Avoiding common errors ensures reliable current measurements, crucial for maintaining electrical system health and efficiency.

How to Measure Current: A Comprehensive Guide

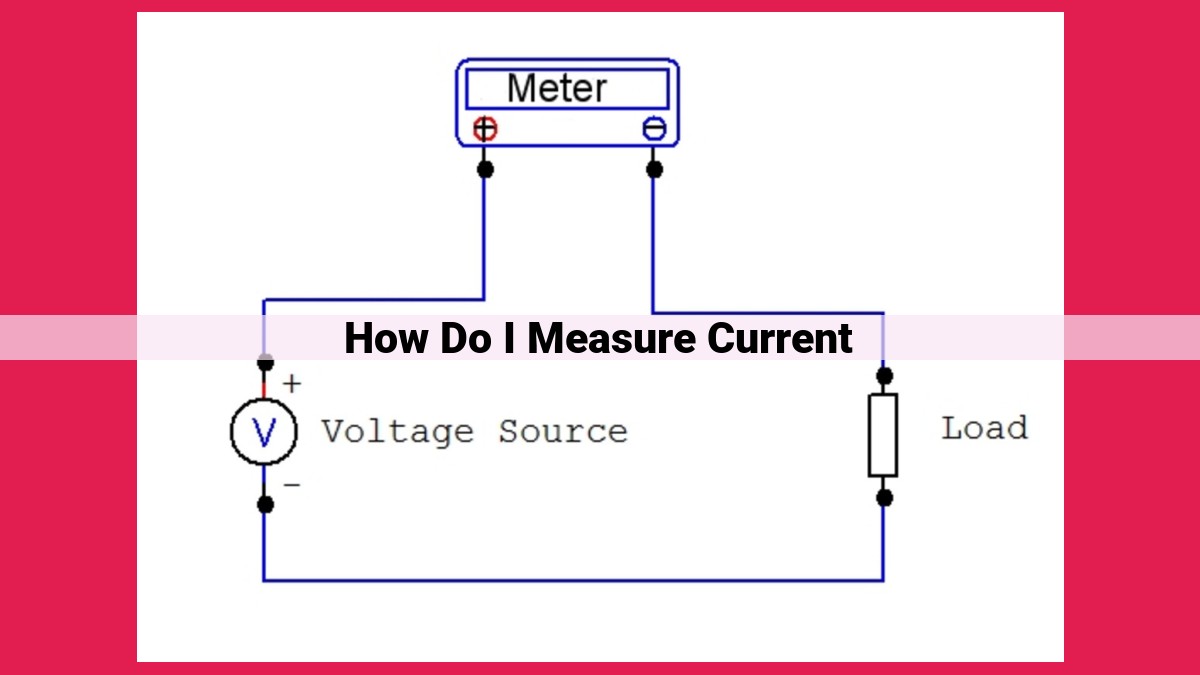

Understanding how to measure current is crucial in the world of electricity. Current, the flow of electrical charge, plays a significant role in powering our devices and ensuring the proper functioning of electrical systems. Without accurate current measurements, we risk electrical hazards and malfunctions. This comprehensive guide will explore the various methods and instruments used for measuring current, empowering you with the knowledge to tackle electrical projects with confidence.

Primary Current Measuring Instruments:

Ammeters, the fundamental current measuring tool, rely on the principles of electromagnetism to detect and quantify current flow. Inside ammeters, a galvanometer deflects a needle proportionally to the current passing through it. Knowing the relationship between deflection and current, we can directly measure current strength.

Non-Contact Current Measurement Techniques:

In situations where it’s impractical or dangerous to make direct contact with electrical components, non-contact current measurement techniques come to the rescue.

-

Hall Effect Sensor: Utilizes the Hall Effect, where a magnetic field perpendicular to the current flow induces a voltage proportional to the current. This enables contactless measurement, making it ideal for high-voltage applications.

-

Rogowski Coil: An innovative current sensor that encircles the conductor with a flexible coil. By measuring the voltage induced in the coil, we can indirectly determine the current flowing through the conductor. Its flexible nature allows for convenient measurements in tight spaces.

High-Precision Current Sensing Methods:

For highly sensitive applications, precision current sensing methods are essential.

-

Fluxgate Sensor: Employs a magnetic core that saturates at specific current levels. By monitoring the saturation point, we achieve highly accurate current measurements even in the presence of external magnetic fields.

-

Zero-Flux Current Transformer: A transformer with a unique design that cancels out the magnetic flux produced by the primary current. This results in exceptional precision at high frequencies, surpassing traditional current transformers.

Convenient and Non-Invasive Measurements:

For quick and accessible current measurements, non-invasive methods offer convenience.

-

Clamp-On Ammeter: A versatile tool that clamps around the conductor, measuring current without breaking the circuit. Its ease of use and safety make it a popular choice for field technicians.

-

Digital Multimeter: A versatile instrument capable of measuring various electrical parameters, including current. Its compact size and digital display provide accurate and convenient readings.

Primary Current Measuring Instruments

In the realm of electrical applications, measuring current accurately is a crucial undertaking. For this purpose, we employ primary current measuring instruments such as the ammeter and the galvanometer.

Ammeter: Unveiling the Essentials

The ammeter, a fundamental tool in electrical measurement, stands out with its ability to quantify the flow of electric current. At its core lies a galvanometer, a sensitive device that detects and indicates the presence of an electric current.

Galvanometer: The Guiding Light

The galvanometer, serving as the heart of an ammeter, operates on the principle of electromagnetic induction. When an electric current traverses its coil, a magnetic field is generated, causing the coil to deflect in proportion to the current strength.

Types of Ammeters: Tailoring to Specific Needs

Ammeters come in various types, each tailored to specific measurement requirements. The moving-coil ammeter, with its high sensitivity and accuracy, remains a popular choice. The moving-iron ammeter employs a pivoted iron vane that responds to changes in magnetic field, offering a rugged and reliable option.

By understanding the principles and applications of these primary current measuring instruments, we gain a deeper appreciation for the meticulous art of electrical measurement.

Non-Contact Current Measurement Techniques:

- Hall Effect Sensor: Principle, advantages, and applications

- Rogowski Coil: Design, operation, and unique features

Non-Contact Current Measurement Techniques

When measuring current in electrical applications, precision and safety are paramount. Non-contact current measurement techniques offer a solution, eliminating the need for direct contact with live conductors, enhancing both safety and convenience. These techniques have revolutionized the industry, making it possible to obtain accurate measurements without the risk of electrical shock or disruption to the circuit.

The Hall Effect Sensor is a prime example of non-contact current measurement technology. It utilizes the Hall Effect, a phenomenon where a magnetic field perpendicular to a current-carrying conductor induces a voltage difference across the conductor. This voltage is proportional to the current flowing through the conductor. By measuring this voltage, the Hall Effect Sensor provides a safe and accurate method of current measurement. Its advantages include non-invasive operation, compact size, and wide operating range, making it ideal for various applications, such as motor control and battery monitoring.

Another innovative technique is the Rogowski Coil, a flexible coil that surrounds the conductor carrying current. The coil’s design creates a magnetic field proportional to the current flowing through the conductor. By measuring the voltage induced in the coil, the Rogowski Coil provides an accurate representation of the current without making electrical contact. This feature makes it suitable for measuring currents in high-voltage or inaccessible locations, where direct contact would be hazardous or impractical.

In conclusion, non-contact current measurement techniques offer a safer, more convenient, and often more accurate approach to measuring current than traditional methods. Whether it’s the Hall Effect Sensor’s compact design or the Rogowski Coil’s flexibility, these techniques empower electricians, engineers, and researchers with the ability to measure current in a wide range of applications while ensuring their safety and the integrity of the circuit under test.

High-Precision Current Sensing Methods

When it comes to measuring current in electrical applications, precision is paramount. This is where high-precision current sensing methods come into play, enabling accurate and reliable measurements that are crucial for optimal system performance.

One advanced technique is the Fluxgate Sensor, a высокоточный sensor that employs advanced technology to accurately detect and measure current flow. Fluxgate sensors are particularly useful in applications requiring extremely high accuracy, such as power grid monitoring and precision testing.

Another high-precision method is the Zero-Flux Current Transformer (ZCT). Unlike traditional current transformers, ZCTs provide exceptional precision at high frequencies, making them ideal for measuring rapidly varying currents. Their unique design allows for accurate measurements without the need for calibration or external power sources.

Whether you’re dealing with high-power systems or intricate electronic circuits, choosing the right current sensing method is essential. Understanding the capabilities and limitations of each technique will help you make informed decisions and ensure reliable, accurate current measurements.

Convenient and Non-Invasive Current Measurements

In the realm of electrical engineering, where precision and safety are paramount, non-invasive current measurement techniques play a crucial role. These methods allow you to obtain accurate readings without disrupting or modifying the electrical circuit.

Clamp-On Ammeter: A Safe and Versatile Tool

The clamp-on ammeter is a versatile instrument that effortlessly measures current without making electrical connections. Its secret lies in the Hall effect sensor, which detects the magnetic field generated by the current flowing through a conductor. Simply clamp the ammeter around the conductor, and it instantly displays the current value. This non-contact approach ensures safety and avoids circuit interruptions.

Digital Multimeter: A Multifaceted Measuring Marvel

The digital multimeter is a must-have for any electrician’s toolbox. This versatile device can measure not only current but also voltage, resistance, and other electrical parameters. Its compact size and easy-to-read display make it an indispensable companion for quick and accurate measurements.

When selecting a clamp-on ammeter or digital multimeter, consider factors like the measurement range, accuracy, and safety ratings. These instruments provide convenient and non-invasive solutions for current measurement, ensuring the safety and efficiency of your electrical endeavors.

Additional Considerations for Current Measurement

Understanding the different methods and instruments available for current measurement is only part of the process. Careful consideration must also be given to selecting the most appropriate method for a given application and choosing the right instrument for the job. Additionally, it’s crucial to be aware of potential sources of error and how to mitigate them.

Determining the Right Measurement Method

The ideal current measurement method depends on several factors, including:

- Precision requirements: How accurate does the measurement need to be?

- Current magnitude: What range of currents is expected?

- Environmental conditions: Where and how will the measurement be taken?

- Non-intrusive nature: Is it necessary to avoid disrupting the circuit being measured?

Instrument Selection Criteria

Once the measurement method is determined, the next step is to choose the instrument. Consider the following criteria:

- Accuracy and resolution: How precise should the readings be?

- Measurement range: Does the instrument cover the expected current range?

- Safety features: Is the instrument designed to protect against overcurrents or faults?

- Ease of use: Is the interface intuitive and user-friendly?

Minimizing Error

Several factors can introduce error into current measurements, such as:

- Instrument calibration: Ensure the instrument is regularly calibrated to maintain accuracy.

- Connection resistance: Poor connections can create resistance that affects readings.

- Magnetic fields: External magnetic fields can interfere with measurements.

- Temperature fluctuations: Changes in temperature can alter the sensitivity of sensors.

To mitigate errors, follow these strategies:

- Use proper calibration and maintenance procedures.

- Ensure good contact between the instrument and the circuit.

- Shield instruments from external magnetic fields.

- Control temperature variations.