Unlock The Rainbow Of Copper: From Natural Hues To Electroplated Shimmers

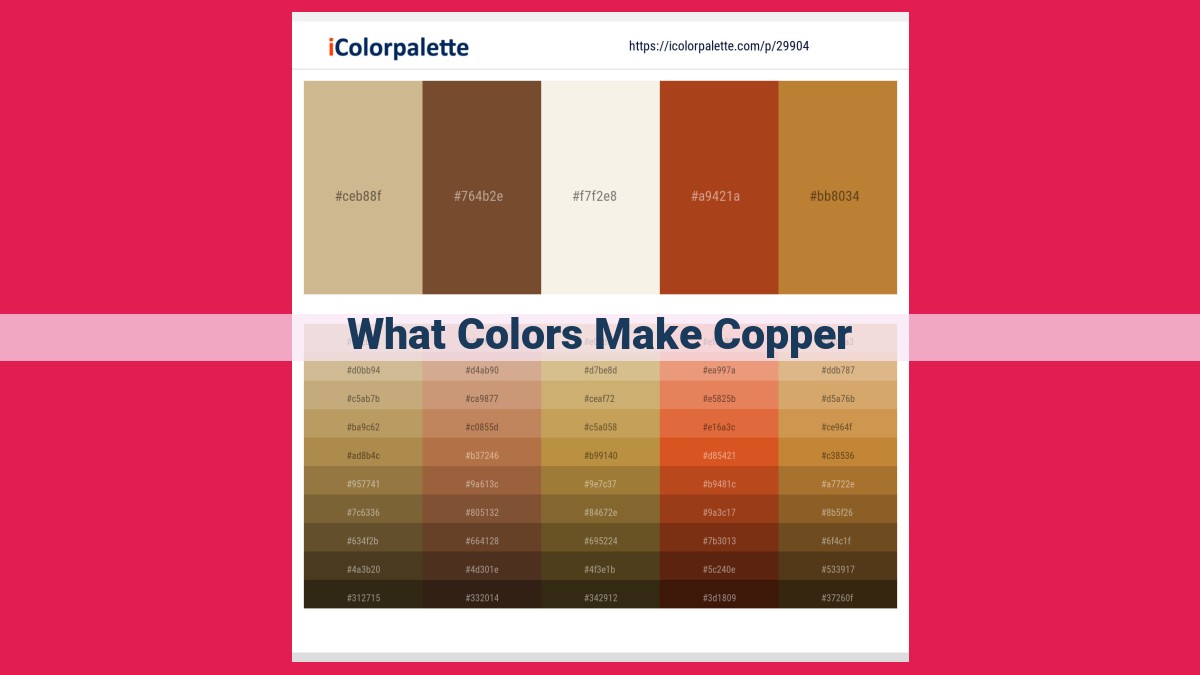

Copper’s hues range from its intrinsic reddish-brown to vibrant greens and blues created by oxidation. Alloys such as brass, bronze, and cupronickel introduce golden, bronze, and silvery-white tones. Chemical reactions with sulfate and carbonate produce blue and green hues, while electroplating transforms copper’s surface with metallic coatings of various colors.

Copper’s Intrinsic Hues: A Journey of Color and Transformation

Copper, an element deeply intertwined with human history, is renowned for its versatile and mesmerizing hues. From the rich, reddish-brown of pure copper to the emerald greens and azure blues of its patinated forms, copper’s color palette is a testament to its multifaceted nature. Embark on a journey to explore the remarkable color transformations of this enigmatic metal.

Copper’s Intrinsic Glow

In its pure form, copper gleams with a lustrous reddish-brown color, a hue that has fascinated humans for millennia. This innate color is a result of copper’s unique electronic structure, which allows it to reflect warm reddish tones while absorbing bluish hues.

Oxidation and Patination: Unveiling Green and Blue

When exposed to the elements, copper oxidizes, forming a protective layer that protects the metal from further corrosion. This oxidation process gives rise to the distinctive green and blue hues that are synonymous with copper. The chemical compound copper oxide is the primary catalyst behind this spectacular transformation.

Alloy Alchemy: Brass, Bronze, and Cupronickel’s Tapestry

Copper’s versatility extends beyond its pure form. When combined with other metals, copper forms alloys that exhibit a broader spectrum of colors. Brass, an alloy of copper and zinc, shimmers with a golden hue. Bronze, a combination of copper and tin, boasts a range of reddish-brown to golden-brown tones. Cupronickel, an alloy of copper and nickel, gleams with a silvery-white appearance.

Chemical Connections: Copper’s Dance with Color

Copper’s intriguing color transformations are not limited to oxidation. Its interactions with chemical compounds also give rise to vibrant hues. Copper sulfate, a soluble blue salt, forms when copper reacts with sulfuric acid. Copper carbonate, a green pigment, results from copper’s interaction with carbon dioxide. These chemical reactions further enrich the color palette of this fascinating metal.

Electroplating’s Metallic Majesty: Surface Transformations

Electroplating, a precise process, allows for tailored modifications to copper’s surface color. By depositing a thin metallic coating onto the copper surface, electroplating transforms its appearance into a kaleidoscope of metallic finishes. From shimmering gold to sleek silver, electroplating unlocks a universe of color options.

Copper’s myriad colors are a testament to its versatility and beauty. From the intrinsic glow of pure copper to the patinated hues of its oxidized forms, and from the alloy alchemy of brass, bronze, and cupronickel to the chemical interactions and electroplating transformations, copper presents a captivating journey through the realm of color. Its enduring appeal ensures that copper will continue to inspire and amaze for generations to come.

Oxidation and Patination: Nature’s Alchemy of Color on Copper

Copper, a versatile metal that has captivated artisans for centuries, reveals a hidden palette when exposed to nature’s touch. As oxidation, the process of chemical interaction with oxygen, takes hold, a transformation occurs, unlocking a vibrant tapestry of patina—the distinctive green and blue hues that adorn so many iconic copper structures and objects.

At the heart of this alchemy lies copper oxide, a chemical compound responsible for the patina’s mesmerizing shades. As copper oxidizes, a thin layer of copper oxide forms on its surface. This layer is porous, allowing moisture and oxygen to further penetrate and interact with the metal. Over time, this interaction intensifies, resulting in a thick patina that becomes an integral part of the copper’s character.

The color of the patina depends on the thickness and composition of the copper oxide layer. Thicker layers typically produce darker green hues, while thinner layers reveal lighter shades of blue. The presence of other elements, such as chlorine or sulfur, can further influence the patina’s coloration, creating a diverse range of hues.

The patina serves not only as an aesthetic enhancement but also as a protective barrier. It slows down the rate of further oxidation, preventing the underlying copper from corroding. This natural protective coating has allowed countless copper structures to withstand the ravages of time, preserving their beauty for generations to come.

So, as you gaze upon the verdant domes and turquoise statues adorned with copper patina, marvel at the artistry of nature’s alchemist. It is in these vibrant hues that the story of copper’s journey unfolds, a testament to the enduring beauty and transformative power of time.

Alloy Alchemy: Brass, Bronze, and Cupronickel’s Tapestry

Copper, with its captivating reddish-brown hue, has played a crucial role in art, architecture, and industry for centuries. However, when this versatile metal joins forces with other elements, it transforms into a myriad of colors and alloys, each possessing unique properties and charm.

Brass: The Golden Child

When copper embarks on a journey with zinc, the result is brass, an alloy known for its warm, golden hue. The ratio of copper to zinc determines the exact shade, ranging from pale yellow to rich amber. Brass has remarkable malleability, making it an ideal choice for intricate designs and musical instruments.

Bronze: History’s Enduring Ally

Bronze, an age-old alloy, emerges from the union of copper and tin. This strong and resilient material has left an indelible mark on history, from ancient sculptures to modern-day weaponry. Bronze possesses a distinctive reddish-brown to golden-brown color that has graced countless artifacts and architectural wonders.

Cupronickel: A Silvery Revelation

Copper’s versatility extends even further with cupronickel, an alloy that blends copper with nickel. This marriage produces a silvery-white sheen that mimics the appearance of silver. Cupronickel is highly resistant to corrosion, making it invaluable in marine applications and coinage.

The alchemy of copper alloys is a testament to the remarkable properties of this transformative metal. From the golden gleam of brass to the enduring strength of bronze and the silvery sheen of cupronickel, these alloys have shaped our world in countless ways.

Copper’s Kaleidoscope of Colors: A Chemical Connection

From the reddish hues of its pure form to the vibrant greens and blues of its patinated state, copper’s ability to transform its appearance through chemical reactions is a testament to its multifaceted nature.

Copper Sulfate: A Blue Symphony

When copper dances with sulfuric acid, a soluble blue salt called copper sulfate emerges. This compound finds its home in the depths of swimming pools and the vibrant canvas of seashells, contributing their distinctive azure shimmer. The creation of copper sulfate is a testament to copper’s affinity for forming complexes with other elements.

Copper Carbonate: A Verdant Canvas

Copper’s artistry extends beyond its interactions with acids. When it encounters carbon dioxide, it transforms into copper carbonate, a verdant green pigment that adorns the roofs of centuries-old buildings and the patina of copper sculptures. This chemical reaction highlights copper’s ability to form stable inorganic compounds, adding to its durability and aesthetic appeal.

Beyond Blue and Green: The Magic of Copper’s Reactions

The color palette of copper knows no bounds. It reacts with other elements to create a kaleidoscope of hues. Brass, an alloy of copper and zinc, shimmers with a golden glow. Bronze, born from the union of copper and tin, boasts reddish-brown to golden-brown undertones. Cupronickel, a harmonious blend of copper and nickel, exudes a silvery-white elegance.

Copper’s Enduring Legacy: A testament to Its Versatility

Copper’s ability to transform its appearance through chemical reactions not only adds to its aesthetic allure but also underscores its versatility and durability. Over time, copper’s patina serves as a protective layer, safeguarding the metal from corrosion while enriching it with a timeless beauty. From ancient sculptures to modern architectural masterpieces, copper’s enduring legacy is a testament to its ability to stand the test of time and enchant the human eye.

Electroplating’s Metallic Majesty: Unveiling Copper’s Surface Transformations

Electroplating, a transformative process that has captivated artisans and industries alike, grants copper a newfound allure by enhancing its surface with metallic coatings. This technique, rooted in the principles of electrochemistry, holds the power to alter copper’s appearance, adding a captivating luster and a fascinating array of metallic hues.

The Electroplating Process: A Symphony of Electrons

Envision a copper object immersed in an electrolytic bath, a specialized solution containing metal ions and other compounds. When an electric current flows through this solution, electrons from the copper object are drawn towards the positive electrode. These electrons bond with the metal ions in the bath, causing them to deposit as a thin layer of metal onto the copper’s surface. This layer, meticulously controlled by various factors such as the voltage, time, and composition of the bath, plays the starring role in transforming copper’s appearance.

A Kaleidoscope of Metallic Finishes

Electroplating opens the door to a world of metallic finishes, allowing artisans and manufacturers to customize copper surfaces to their heart’s content. Silver, gold, and nickel stand as just a few examples of the possible transformations. By fine-tuning the electroplating process, it becomes possible to achieve distinct shades within each metal, ranging from a warm, rosy gold to a cool, silvery white.

Copper’s versatility shines through in electroplating, enabling the creation of surfaces that mimic the textures of other materials. From the brushed elegance of satin to the mirror-like brilliance of polished chrome, electroplating bestows upon copper the ability to emulate a wide spectrum of aesthetic textures.

Unveiling Copper’s Inner Radiance

Beyond its surface-level transformations, electroplating also unveils copper’s hidden radiance. By selectively electroplating specific areas of a copper object, artisans can create intricate patterns and designs that highlight its natural beauty. This technique, known as electroforming, elevates copper’s appeal, turning it into a canvas for artistic expression.

Applications that Span Industries

Electroplating’s transformative abilities extend far beyond the realm of aesthetics. In the realm of engineering, electroplating enhances copper’s corrosion resistance, extending its lifespan and safeguarding its integrity in demanding environments. Similarly, within the electronics industry, electroplating plays a crucial role in ensuring the durability and conductivity of copper components.

Electroplating, with its ability to bestow upon copper a dazzling array of metallic finishes and textures, emerges as a transformative art form. This process not only elevates copper’s aesthetic appeal but also enhances its functionality, making it a versatile material that finds its place in countless industries and applications. As we delve deeper into the realm of electroplating, we uncover the endless possibilities that await this remarkable metal.