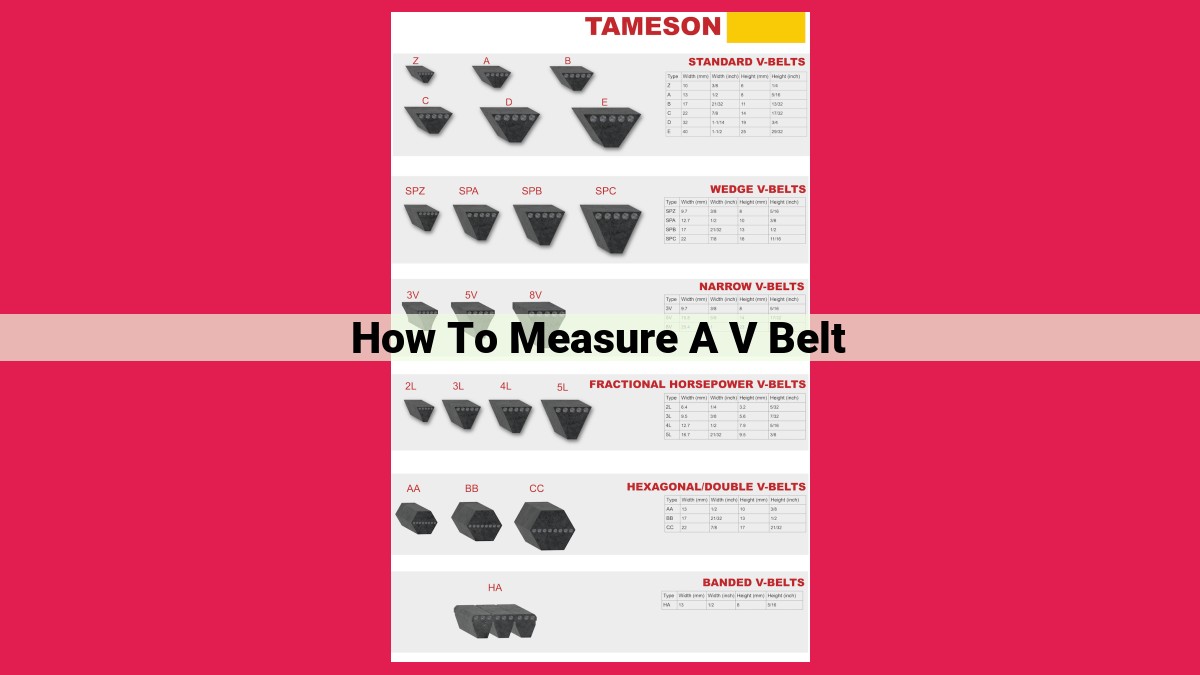

Comprehensive V-Belt Measurement Guide: Determining Outer Circumference, Inner Circumference, Width, And Pitch Length

To measure a V-belt, begin by determining its outer circumference, which is the total length of the belt’s outer edge. Next, measure the inner circumference, or the distance around the belt’s inner edge where it fits around pulleys. Measure the belt width, denoting the distance between its top and bottom surfaces, and the pitch length, which accounts for belt curvature and ensures proper tension. Consider using a belt gauge for precise measurement. For a double V-belt, measure both V-shaped sections. If the belt is cogged, factor in the teeth for increased grip.

How to Measure a Belt’s Outer Circumference

When it comes to belts, understanding their dimensions is crucial, especially for proper fit and function. Measuring the outer circumference is one essential aspect of this process. The outer circumference, also known as the belt’s perimeter, is the total length of its outer edge. Determining this measurement effectively gives you the belt’s complete length.

To measure the outer circumference precisely, follow these simple steps:

- Identify the outer edge of the belt, which is the outermost surface.

- Use a flexible measuring tape or string to trace along the outer edge. Ensure that the tape stays taut throughout the measurement.

- Record the length indicated on the tape or string. This value represents the belt circumference.

By accurately measuring the outer circumference, you can determine the belt’s overall length, ensuring a suitable fit for your specific needs.

Measuring the Inside Circumference of a Belt

When it comes to belts, the inside circumference is crucial for ensuring proper fit and functionality. Also known as the inner circumference, it measures the length of the belt’s inner edge, the area that wraps around the pulley.

Accurately measuring the inside circumference is essential for several reasons. First, it helps you determine the correct belt size for your pulley. If the belt is too short, it will not fit properly and may slip or break. If it’s too long, it will be loose and potentially cause damage to the system.

Secondly, the inside circumference plays a role in maintaining proper belt tension. The tension must be correct to ensure optimal power transmission and prevent premature belt wear. By accurately measuring the inside circumference, you can calculate the required belt length and tension.

To measure the inside circumference, you can use a belt gauge for precise results. Alternatively, you can use a tape measure or string as follows:

- Wrap the tape measure or string around the inner edge of the belt, where it fits around the pulley.

- Mark the point where the tape measure or string meets itself.

- Measure the length between the two marks. This is the inside circumference of the belt.

Remember that when measuring a double V-belt, you need to consider both V-shaped sections to calculate the correct inside circumference.

By taking the time to accurately measure the inside circumference of your belt, you can ensure proper fit, optimal performance, and extended belt life.

Measuring Belt Width: Understanding the Belt’s Dimensions

When measuring a belt, one crucial aspect to consider is its width. This dimension represents the distance between the top and bottom surfaces of the belt, and it plays a significant role in determining its performance and compatibility with the intended application.

Furthermore, understanding the concept of belt cross-section is key to describing the shape and dimensions of a belt. The cross-section provides a comprehensive profile of the belt’s structure, including its width, thickness, and any specific features (e.g., teeth, cogs). By analyzing the cross-section, you can gain insights into the belt’s functionality and suitability for different applications.

For instance, wider belts typically transmit more power and can withstand heavier loads compared to narrower belts. This is because a wider belt has a larger contact surface area with the pulleys, resulting in reduced slippage and improved power transfer. On the other hand, narrower belts are more flexible and can operate over smaller pulleys, making them suitable for applications where space constraints are a concern.

By accurately measuring the belt width and understanding the belt cross-section, you can ensure that you select the right belt for your specific needs. This will not only optimize the performance of your system but also prevent premature belt failure and costly downtime.

Mastering Belt Measurement: Exploring the Pitch Length

In the realm of belt maintenance and replacement, understanding the intricacies of belt measurement is crucial. Among the various parameters, the pitch length holds a pivotal role in ensuring optimal belt performance. Let’s delve into this essential concept.

The pitch length, also known as the effective belt length, is a crucial measurement that represents the distance between the centers of the pulleys on which the belt operates. Unlike the outer or inner circumference, the pitch length takes into account the curvature of the belt as it wraps around the pulleys.

Why is the pitch length so important? It’s all about maintaining proper belt tension. When the belt is installed at the correct pitch length, it ensures adequate tension to transmit power effectively without slipping or overstretching. This optimal tension also extends the belt’s lifespan and minimizes the risk of premature failure.

Measuring the pitch length accurately is essential. One precise method involves measuring the distance between the pulley centers, accounting for any obstacles or idlers that may alter the path of the belt. This approach ensures that the belt will fit snugly and perform as intended.

By understanding the concept of pitch length and its significance in belt measurement, you’re equipped to maintain and replace belts with confidence. Remember, a properly measured belt is a key component in ensuring efficient power transmission and long-lasting performance.

Belt Gauges: Precision Tools for Accurate Belt Length Measurement

When it comes to measuring belt length, accuracy is paramount. Traditional methods like using a tape measure or string can lead to errors, especially with V-belts and cogged V-belts. This is where belt gauges step in as indispensable tools for precise and reliable belt length measurement.

Belt gauges are specialized instruments designed specifically for measuring the length of belts. They feature a series of pegs or marks that correspond to different belt sizes. To use a belt gauge, simply place the belt around the pegs or marks until it fits snugly. The corresponding measurement on the gauge will then indicate the belt’s length.

Benefits of Using a Belt Gauge:

-

Precision: Belt gauges provide unparalleled accuracy, ensuring that you get the exact length of your belt. This is crucial for proper belt tension and avoiding premature belt failure.

-

Ease of Use: Belt gauges are incredibly easy to use, even for beginners. Simply place the belt around the pegs or marks and read the measurement.

-

Time-Saving: Measuring a belt with a belt gauge is a quick and efficient process, saving you valuable time compared to manual methods.

-

Multiple Belt Types: Belt gauges are designed to accommodate various belt types, including V-belts, cogged V-belts, and serpentine belts.

In addition to their precision and ease of use, belt gauges also offer convenience and portability. They are compact and easy to store, making them ideal for field measurements or mobile repair work.

By investing in a belt gauge, you will equip yourself with a tool that will deliver accurate and reliable belt length measurements for years to come.

Measure Belt Length with a Tape Measure or String: A Step-by-Step Guide

Knowing the precise length of a belt is crucial for ensuring proper fit and performance. While you can use specialized tools like belt gauges, a simple tape measure or string can also do the trick. Here’s a step-by-step guide to help you out:

Materials You’ll Need

- Tape measure or string

- Pen or marker

Step 1: Choose the Measuring Point

If the belt is already mounted on the pulleys, measure the length from pulley center to pulley center. For belts that are not yet installed, measure the length from the end of one belt loop to the end of the opposite belt loop.

Step 2: Mark the Belt

Place the tape measure or string along the measuring path. Use a pen or marker to mark the end points of the belt length.

Step 3: Measure the Distance

Hold the tape measure or string taut and read the measurement at the point where the marked end points meet. This will give you the length of the belt.

Additional Tips

- For more accurate results, use a metal tape measure.

- If the belt is curved or has multiple strands, straighten it out before measuring.

- Allow for some extra length when measuring the belt, especially for belts that will be under heavy load or operate at high speeds.

Measuring a belt length with a tape measure or string is a simple and effective method. By following these steps, you can ensure an accurate measurement that will help you select the correct belt for your application. Remember, proper belt length is essential for optimum performance and extended belt lifespan.

How to Measure a Double V-Belt

When it comes to ensuring the optimal performance of your machinery, understanding the precise dimensions of your double V-belt is crucial. These versatile belts, commonly used in industrial and automotive applications, provide an efficient means of power transmission with their distinctive V-shaped cross-section.

Unraveling the V-Belt Anatomy

Before embarking on the measurement process, it’s essential to familiarize yourself with the key anatomical features of a double V-belt. As its name suggests, it comprises two V-shaped sections, each designed to fit snugly into the corresponding grooves of the pulleys. The top width refers to the distance between the outer edges of the V-shaped sections, while the thickness is the height of the belt measured from the apex of the V to its base.

Embracing Precision: Measuring the Double V-Belt

To obtain an accurate measurement, follow these meticulous steps:

-

Outer Circumference Measurement: Measure the outer edge of the belt, following its natural curvature. This measurement provides the total length of the belt.

-

Inner Circumference Measurement: Carefully measure the inner edge of the belt, where it fits around the pulleys. This effective length is crucial for determining the correct belt tension.

-

Belt Width Measurement: Place the belt on a flat surface and measure the distance between the top and bottom V-shaped sections. This belt width ensures proper fitment within the pulley grooves.

-

Considering Double V-Belt Peculiarities: With double V-belts, it’s important to measure both sections separately and combine the measurements to obtain the total belt width.

-

Verification with a Belt Gauge: Utilize a specialized belt gauge for precise measurement, eliminating any guesswork associated with manual methods.

Measure a Cogged V-Belt:

- Define a cogged belt as a V-belt with teeth or cogs for increased grip.

- Explain the purpose of the cogs and how they affect the belt’s performance.

- Provide specific instructions for measuring cogged V-belts to ensure proper fitment.

Measuring a Cogged V-Belt: Ensuring Optimal Performance and Fit

Cogged V-belts, also known as toothed belts, are a crucial component in various mechanical systems, transmitting power efficiently between pulleys. Unlike traditional V-belts, cogged V-belts feature teeth or cogs that interlock with corresponding grooves on the pulleys, resulting in increased grip and reduced slippage. To ensure optimal performance and fit, it is essential to measure cogged V-belts accurately.

Benefits of Cogged V-Belts

- Enhanced Grip: The teeth or cogs on the belt provide a positive grip against the pulley grooves, preventing slippage and maintaining constant tension.

- Reduced Noise and Vibration: The interlocking action of the teeth reduces noise and vibration during operation.

- Increased Efficiency: The positive grip reduces power loss and improves overall efficiency of the system.

Measuring a Cogged V-Belt

-

Determine the Pitch:

The pitch of a cogged V-belt is the distance between adjacent teeth. It is typically measured in millimeters or inches. To determine the pitch, measure the distance between any two adjacent teeth and divide by the number of teeth in between.

-

Measure the Outer Circumference:

The outer circumference is the total length of the belt along its outer edge. To measure it, wrap a tape measure around the belt and record the measurement.

-

Measure the Inner Circumference:

The inner circumference is the length of the belt along its inner edge, where it fits around the smaller pulley. Measure this by wrapping the tape measure around the belt and recording the measurement.

-

Calculate the Effective Length:

The effective length of a cogged V-belt is the distance between the centers of the pulleys, taking into account the curvature of the belt. To calculate this, use the following formula:

Effective Length = (Outer Circumference - Inner Circumference) / 2 -

Use a Belt Gauge (Optional)

Belt gauges are specialized tools designed to accurately measure the length of cogged V-belts. They provide a quick and convenient method for obtaining precise measurements.

Tips for Accurate Measurement

- Always measure the cogged V-belt when it is not installed on the pulleys to avoid distortion.

- Ensure that the tape measure is held straight and parallel to the edge of the belt.

- Take multiple measurements to ensure accuracy and consistency.

- Refer to the manufacturer’s specifications or consult a professional for proper installation guidelines.